The vinyl esters industry is entering a decade of transformation, driven by sustainability, durability, and expanding applications across marine, wind energy, and industrial sectors. As industries worldwide seek materials that balance strength, chemical resistance, and eco-friendliness, vinyl esters are emerging as a cornerstone of modern composites and infrastructure solutions.

Key Highlights by 2031

-

Size & Share

-

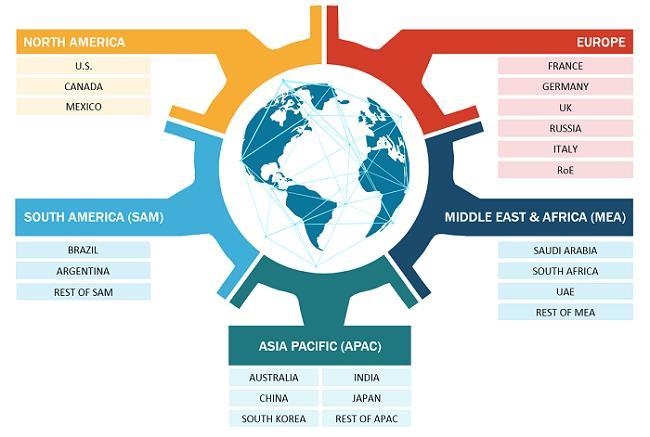

Vinyl esters are expanding across all major regions, with Asia Pacific leading adoption due to rapid industrialization and infrastructure growth.

-

North America and Europe remain strong markets, driven by innovation and sustainability mandates.

-

South and Central America are emerging as promising regions with growing demand in pulp & paper and construction.

-

-

Trends

-

Rising demand for bisphenol A, novolac, brominated fire retardant, and other vinyl ester products.

-

Growing emphasis on applications in pipes & tanks, marine, wind energy, FGD & precipitators, pulp & paper, and other industrial uses.

-

Increasing focus on eco-friendly and fire-retardant solutions to align with global sustainability goals.

-

Expansion of applications in renewable energy and marine infrastructure, driven by durability and regulatory compliance.

-

-

Analysis & Forecast

-

By 2031, vinyl esters will be integral to sustainable supply chains, replacing traditional resins in key sectors.

-

Bisphenol A and novolac-based vinyl esters are expected to dominate due to their versatility and performance.

-

Sustainability-driven innovations, including low-emission and recyclable composites, are projected to gain traction globally.

-

Strategic collaborations between resin producers and end-use industries will drive innovation and market expansion.

-

Global and Regional Insights

-

Asia Pacific: Dominates the market with strong growth in China, India, and Southeast Asia. Marine and wind energy are key drivers.

-

North America: Focused on advanced vinyl ester technologies for industrial and infrastructure applications.

-

Europe: Driven by stringent environmental regulations and renewable energy mandates. Vinyl esters are increasingly replacing traditional resins.

-

South & Central America: Emerging opportunities in pulp & paper, construction, and industrial modernization.

Updated Industry News

-

Recent innovations include fire-retardant vinyl esters designed for marine and wind energy applications.

-

Manufacturers are investing in digital inspection and monitoring systems to enhance efficiency and safety.

-

Strategic mergers and acquisitions are strengthening global supply chains and expanding product portfolios.

-

The industry is witnessing integration of vinyl esters in renewable energy projects, particularly in wind turbine blades and marine composites.