In the modern construction and engineering industry, the journey from early design concepts to fully realized structures is becoming increasingly refined. One of the most essential aspects of this journey is the integration of one of the shops, detailed design plans, and advanced rendering that bring projects to life. This complete structural design process ensures that each element of a project is carefully planned, coordinated, and executed with accuracy.

Importance of the shop picture

Shop pictures form the foundation of a successful construction project. These highly elaborate diagrams are beyond the general schemes created during the initial design stages. These include accurate dimensions, construction details, material specifications, and installation instructions.

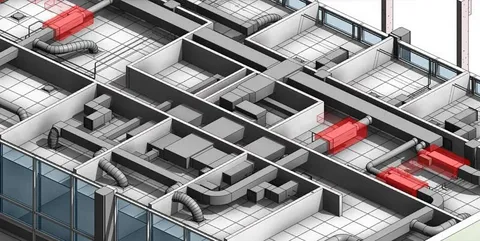

Unlike architectural drawings that often provide a broad view, the drawing pictures focus on the practical, step-by-step process of creating components that are basically fit in the overall structure. For example, the shop produces drawings for steel beams, HVAC systems, or electrical layouts, to ensure that components are manufactured to specifications and correctly installed on the site.

Without a picture of the exact shop, misunderstandings and errors can occur, causing expensive delays and re-functioning. Therefore, these documents are considered a blueprint for execution, and a shared vision is guided by fabricators, contractors, and engineers.

Reduction of the difference in structural details

Structural details serve as a bridge between ideological design and shop images. This involves translating engineering calculations and architectural concepts into detailed structural models that address both function and viability.

Structural detailers work to ensure that each bolt, joint, and weld is accounted for, while also verifying that the design complies with safety standards and building codes. This phase is important to ensure structural integrity. The Right Time to Open Your Pool?

Modern software tools allow structural detailers to create 3D models that can be easily reviewed and modified before construction. This not only reduces errors but also facilitates coordination between various trades working on the same project.

3D rendering role

While the shop's drawings and structural details focus on accuracy and construction, 3D rendering designs offer visual design. Renderings are photorealistic images that allow stakeholders to imagine the complete structure long before construction begins.

For architects, rendering acts as a tool to convey ideas in ways that traditional blueprints cannot. For engineers and contractors, they provide visual context for better planning and coordination. CAD drafting companies often incorporate rendering into their workflows to save time, highlight potential design conflicts, and streamline the overall process.

In addition, high-quality renderings are frequently used in presentations, marketing materials, and project approvals. They help customers and investors understand the final result and instill confidence in the project.

Complete Workflow: Until the concept is completed

Structural design includes several interacting stages in a well-structured workflow:

Conceptual reagent

As soon as possible, in the earliest phase, architects and engineers consider churning ideas, functionality, aesthetics, and viability. Early drawings and models are made to establish an outline for the project.

design development

Once the concept is approved, a detailed plan is prepared. This phase involves refining the design, calculating loads, and ensuring compliance with building code.

The focus shifts to accurate details that will be used by the fabricator and contractors. Shop pictures are prepared for components such as steel reinforcement, piping, and mechanical systems.

3D modeling and rendering

Advanced software tools turn the design into life-like models and renderings. These allow the virtual walkthrough and visualization of the structure before laying a brick.

Execution and construction

With all the details in place, the actual construction begins. Contractors rely on the shop picture, while customers and managers refer to the rendering to track progress.

Final handover and reviews

After completion, reviews are reviewed against the basic plans and rendering of the project. This ensures that the final structure aligns with expectations.

Structural design technology

The advancement of technology has revolutionized the way structural design is exposed. Building information modeling (BIM), computer-aided design (CAD), and virtual reality tools now make it possible to integrate each stage of the design process in the same digital ecosystem.

With BIM, engineers and architects can cooperate in real time, updating the model and shop drawing together. This level of integration reduces errors and ensures that all stakeholders are working with the most current information.

In addition, virtual reality and promoted reality technologies are now being used to present rendering in immersive formats. Customers are experiencing "walk", layouts, lighting, and spatial flow firsthand before the construction of a building.

Benefits of a complete structural design solution

Bringing the shop pictures, details, and rendering together in the integrated process provides many benefits:

-

Accuracy and precision: Each stage builds on the previous, reducing the possibility of mistakes.

-

Better cooperation: Separate teams can work together and share information on platforms.

-

Time and Cost Savings: Initial detection of design conflicts prevents delays and expensive modifications.

-

Promotional visualization: Customers and stakeholders get a clear understanding of the final product.

-

High-quality results: By integrating technology and expertise, projects are executed to the highest standards.

Application of industries

A full structural design approach is not limited to large-scale buildings. It is equally valuable in areas such as industrial plants, infrastructure projects, residential complexes, nd commercial facilities.

For example, in bridge construction, shop drawings ensure accurate construction of steel girders, while rendering helps to imagine how the bridge is integrated into the surrounding landscape. In residential projects, rendering allows homeowners to look at their future house, while detailed plans guarantee structural security and functionality.

conclusion

Travel from shop drawing to rendering represents a comprehensive approach to structural design that balances technical accuracy with creative views. By integrating each stage in a streamlined workflow, professionals in the construction and engineering industry can distribute projects that meet both functional and aesthetic requirements.

In this developed landscape, the role of CAD drafting services becomes important, which is able to produce teams to produce detailed, accurate, and visually attractive design solutions that ensure the success of the project until the concept is completed.