Printed Circuit Boards (PCBs) are the backbone of modern electronics. From smartphones and laptops to medical equipment and aerospace systems, almost every device relies on a PCB to function. Because of this, PCB reliability is critical. A reliable PCB ensures consistent performance, safety, and longer product lifecycles. When reliability is overlooked, the cost of failures can affect not just production, but also customer trust and long-term business success.

In this article, we’ll break down the key factors that influence PCB reliability, how to test it, and why it matters across industries.

1. What PCB Reliability Really Means

PCB reliability refers to how consistently a board performs under normal operating conditions for its expected lifespan. A reliable PCB should not fail prematurely due to design flaws, poor materials, or environmental stresses.

Instead of looking at reliability as just “not breaking,” think of it as maintaining stable performance over time. This includes signal integrity, thermal management, mechanical durability, and resistance to environmental factors such as moisture, dust, and vibration.

2. Why PCB Reliability Matters in Every Industry

The consequences of PCB failure vary depending on the product, but the impact is always significant.

-

Consumer electronics: A failed PCB can shorten device lifespan and damage brand reputation.

-

Medical equipment: Reliability can directly affect patient safety.

-

Automotive and aerospace: Failures in control systems can lead to safety risks and costly recalls.

-

Telecom and data centers: Downtime caused by PCB issues can lead to service interruptions and financial losses.

Reliability is not just a technical concern; it is also a business and safety priority.

3. Factors That Affect PCB Reliability

Several factors influence how long and how well a PCB will last:

-

Material selection: Substrate quality, copper thickness, and solder mask durability all play a role.

-

Design practices: Poor trace routing, inadequate spacing, or lack of thermal relief can cause early failures.

-

Manufacturing quality: Errors during fabrication, such as poor solder joints or contamination, reduce reliability.

-

Environmental exposure: Heat, humidity, and vibration accelerate wear and failure.

-

Component quality: Even with a strong PCB design, weak components can compromise performance.

Understanding these factors helps manufacturers control risks early in the process.

4. Testing Methods for PCB Reliability

Testing is one of the most effective ways to measure and improve PCB reliability. Common testing methods include:

-

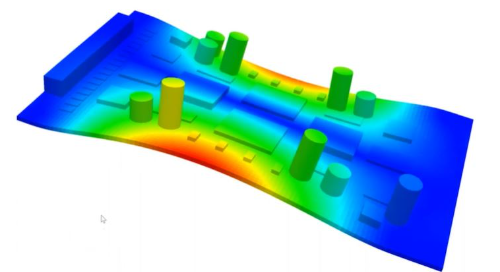

Thermal cycling: Repeatedly heating and cooling the PCB to simulate real-world conditions.

-

Vibration and shock testing: Ensuring the PCB can withstand mechanical stress.

-

Humidity and salt spray tests: Measuring resistance to corrosion and moisture.

-

Electrical testing: Verifying signal integrity and insulation resistance.

-

Accelerated life testing: Pushing the board to its limits to predict long-term performance.

Each test provides valuable data that engineers use to improve designs and confirm that boards meet industry standards.

5. How to Improve PCB Reliability in Design

Strong design practices are the foundation of PCB reliability. Engineers can take several steps to minimize risks:

-

Use wider traces for higher current paths.

-

Maintain proper spacing to reduce risk of short circuits.

-

Apply thermal management strategies, such as heat sinks and vias.

-

Select appropriate laminates and coatings for harsh environments.

-

Follow industry design guidelines like IPC standards.

These steps may add effort during design, but they pay off by reducing failures in production and use.

6. The Role of Manufacturing in Reliability

Even the best design can fail if manufacturing is inconsistent. Manufacturers must focus on:

-

Process control: Precise temperature, pressure, and alignment during fabrication.

-

Inspection and testing: Catching defects before boards leave the factory.

-

Cleanliness: Contamination during assembly can lead to corrosion or solder issues.

-

Skilled workforce: Proper training ensures fewer errors in production.

Partnerships with reliable PCB fabricators are critical to achieving long-term success.

7. Monitoring Reliability in the Field

Reliability does not end after manufacturing. Companies should monitor PCBs during real-world use to gather data for continuous improvement. This includes:

-

Failure reporting systems: Tracking issues to identify patterns.

-

Maintenance records: Using field data to adjust future designs.

-

Feedback loops: Sharing lessons from field performance with design and manufacturing teams.

This ongoing approach ensures that products not only meet expectations today but continue improving over time.

Best Practices for Long-Term PCB Reliability

-

Select materials suitable for the operating environment.

-

Design with margin, not just minimum requirements.

-

Test early and often during development.

-

Work with manufacturers that follow strict quality standards.

-

Collect and analyze data from both lab testing and field use.

Conclusion

PCB reliability is more than just preventing failures. It is about ensuring that products deliver consistent performance, safety, and customer satisfaction throughout their lifecycle. By focusing on design, manufacturing quality, testing, and ongoing monitoring, companies can significantly reduce risk and build stronger, more trustworthy products.

Whether you’re building consumer electronics, medical devices, or aerospace systems, PCB reliability should always be a top priority.