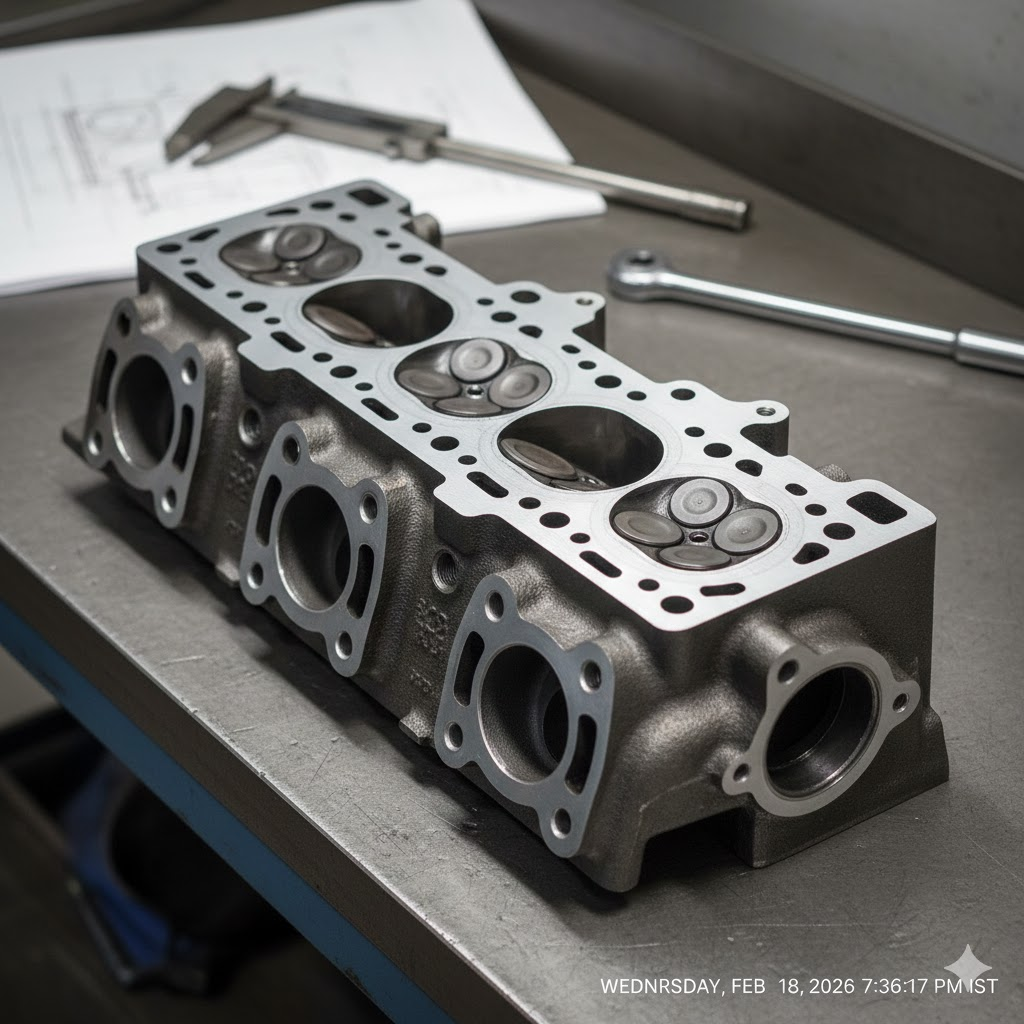

Automotive Cast Iron Cylinder Head is one of the most critical and precision-engineered components in an internal combustion engine. It seals the top of the engine block, housing the combustion chambers, intake and exhaust valves, valve seats, spark plug ports, and coolant passages that together govern the engine's thermal and mechanical performance. Cast iron cylinder heads are specifically engineered for applications requiring exceptional thermal stability, high mechanical strength, and superior vibration damping — characteristics that make them the material of choice for large displacement and heavy-duty diesel engines used in trucks, buses, construction equipment, and industrial machinery.

Compared to aluminum alternatives, cast iron offers significant advantages in durability, wear resistance, and cost-effectiveness, making it foundational to the long service life expectations of the commercial vehicle sector. Manufacturers are continuously investing in enhanced casting techniques, advanced alloy formulations, and design optimizations to ensure cast iron heads remain competitive in an increasingly demanding engine performance environment.

Key Market Drivers

The primary driver of the automotive cast iron cylinder head market is the robust and growing demand for aftermarket services. The world's enormous fleet of older internal combustion engine vehicles — particularly commercial vehicles that operate for decades under heavy-duty conditions — generates a high-volume, reliable demand for durable cylinder head replacements and repairs. As these vehicles age, the aftermarket segment provides a consistent revenue stream that is largely insulated from the near-term fluctuations in new vehicle production cycles.

Request Sample Pages of this Research Study @ https://www.theinsightpartners.com/sample/TIPRE00022355

The second key driver is cast iron's inherent superior durability and thermal resistance. The material's exceptional thermal mass and wear resistance under extreme stress and temperature conditions make it irreplaceable for heavy-duty diesel engines operating in trucks, buses, and industrial machinery. No currently available alternative material matches cast iron's combination of high-temperature performance, machinability, and cost-effectiveness at the scale required by the commercial vehicle industry.

Increasing vehicle production rates — particularly in emerging economies — represent the third major driver. As automotive manufacturing scales up across Asia-Pacific, South America, and the Middle East, core OEM demand for cast iron components expands in direct proportion, particularly in commercial vehicle segments where cast iron remains the dominant cylinder head material.

Market Opportunities

The development of lightweight cast iron alternatives presents a significant and growing opportunity. Advanced materials such as Compacted Graphite Iron (CGI) and ductile iron are enabling manufacturers to produce cylinder heads that are measurably lighter than conventional gray iron components while maintaining equivalent or superior mechanical strength. This lightweighting capability directly addresses the growing regulatory pressure on fuel efficiency and emissions without requiring the complete material transition to aluminum that many passenger car OEMs are pursuing.

Advanced manufacturing processes represent another compelling opportunity. The adoption of 3D core printing for prototype development and production tooling, combined with sophisticated casting simulation software, enables the creation of more complex internal cooling passages, optimized metal distribution, and superior thermodynamic performance. These technologies are helping cast iron cylinder heads remain relevant in an era of tightening emission standards such as BS-VI and Euro VII. Additionally, high-growth markets across Asia-Pacific and South and Central America — where rising vehicle ownership, expanding middle classes, and accelerating industrialization are driving commercial vehicle demand — present substantial geographic expansion opportunities for cylinder head manufacturers.

Order a Copy of this Research Study @ https://www.theinsightpartners.com/buy/TIPRE00022355

Market Segmentation

By engine type, the market encompasses straight or inline engines, V-type engines, and flat engines. Inline and V-type configurations dominate due to their widespread application in commercial trucks, buses, and industrial engines where cast iron's durability is most valued. By vehicle type, heavy commercial vehicles represent the dominant application segment — the segment where cast iron's superior thermal and mechanical properties are most critical and where aluminum has made the least competitive inroad. Light commercial vehicles, passenger cars, and two-wheelers round out the segment landscape, with cast iron maintaining a presence in cost-sensitive markets and specific high-stress applications across all categories.

Regional Insights

Asia-Pacific is both the largest regional market and the fastest-growing, driven by massive automotive production volumes in China and India, rapidly rising vehicle ownership among expanding middle-class populations, and high demand for heavy commercial vehicles across infrastructure-heavy industries. The region's combination of advanced manufacturing processes and emphasis on cost-effective, high-volume production makes it the global center of gravity for cast iron cylinder head manufacturing and consumption.

North America holds a significant market share, anchored by its substantial heavy-duty trucking industry and strong aftermarket demand for high-performance replacement parts. The adoption of advanced CGI alloys in heavy-duty truck engines is a defining regional trend. Europe maintains a large market share, supported by its strong commercial vehicle manufacturing sector and a focus on material efficiency innovations driven by some of the world's strictest emission regulations. While passenger car OEMs increasingly favor aluminum, cast iron continues to play an indispensable role in high-stress diesel and commercial applications across the region.

Competitive Landscape

The market features a competitive mix of major global casting specialists, integrated engine manufacturers, and regional foundry players. Key companies include Toyota Industries Corporation, Yamaha Motor Co. Ltd., Cummins Inc., NEMAK, Silbitz Group GmbH, TEKSID SPA, YASUNAGA Corporation, Sandvik Coromant, Mauss GmbH, and Cooper Corp. Competition centers on precision casting quality, material innovation — particularly CGI adoption — production cost leadership, aftermarket service capabilities, and supply chain reliability for long-term OEM contracts.

Also Available in : Korean German Japanese French Chinese Italian Spanish

Frequently Asked Questions (FAQ)

Q: What are the future trends in the automotive cast iron cylinder head market?

A: Key future trends include increased adoption of CGI and ductile iron for lightweighting, integration of 3D core printing for complex cooling passage design, growth in the remanufactured aftermarket segment, and optimization of cast iron formulations for compliance with tightening global emission standards such as BS-VI and Euro VII.

Q: Who are the leading players in the automotive cast iron cylinder head market?

A: Major companies include Toyota Industries Corporation, Cummins Inc., NEMAK, Silbitz Group GmbH, TEKSID SPA, Yamaha Motor Co. Ltd., YASUNAGA Corporation, and Cooper Corp., among others.

Q: Which vehicle segment drives the most demand for cast iron cylinder heads?

A: Heavy commercial vehicles are the dominant application segment, as their large displacement diesel engines operating under extreme stress and temperature conditions benefit most from cast iron's superior material properties.

Q: What is Compacted Graphite Iron (CGI) and why is it significant?

A: CGI is an advanced cast iron variant offering improved strength-to-weight ratio compared to conventional gray iron, enabling lighter cylinder heads without compromising mechanical performance — directly addressing fuel efficiency and emission reduction requirements.

Q: Which region leads the automotive cast iron cylinder head market?

A: Asia-Pacific is both the largest and fastest-growing regional market, driven by massive automotive production volumes and high commercial vehicle demand in China and India.