An Overview of ABS Plastic Sheet and Its Growing Industrial Consumption

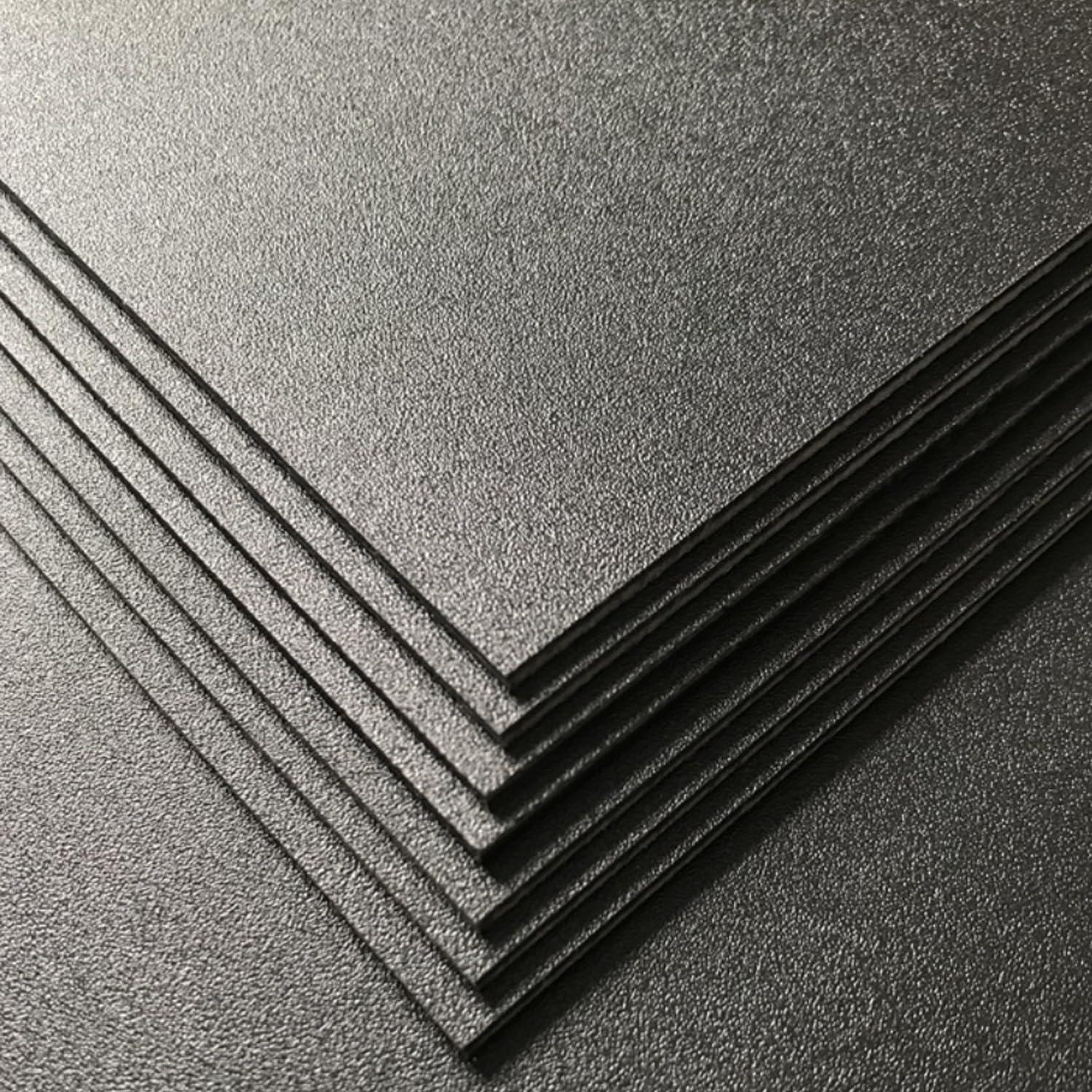

ABS Plastic Sheet is now the most common and popular thermoplastic material, providing a good balance of strength and weight, ABS sheets are produced in monolayer and co-extruded multilayer. Acrylonitrile Butadiene Styrene, commonly known as Abs, is the most widely used materials for low volume prototypes and functional end-use parts. Featuring automotive grade materials, such as woven carbon fiber or fiberglass, this device can withstand harsh environments from the streets into the office.

This ABS sheet is not only tough and light weight. This incredible fusion enables manufacturers to create complex logos without sacrificing strength. Hence, the demand for top quality ABS sheets is growing in India and worldwide as well offering industries a more dependable substitution to metal, wood or other such heavy materials. Today, with the rapid development of large-scale infrastructure and manufacturing industries REQUIRE ABS plastic sheets have been a great help in modern production.

Significant Characteristics That Set ABS Sheets Apart

ABS Plastic Sheets High-impact resistance, stability and g/w machinability. These sheets are mechanically tough and are perfect for uses where they will be used as a protective covering, counter front and dashboards such as an auto interior or enclosures for industrial equipment. Their chemical resistance and moderate heat tolerance makes them suitable for use in demanding applications.

A further advantage is their fine surface structure enable easy painting, printing or thermoforming. This versatility allows them to be used to meet various aesthetic needs, including sample holders, decorative panels and display units. Moulded Products As compared to 3d Wpc Wall Panel Price requirements of interior decoration and other products like ABS, Customized ABS Sheet for the most part has evolved as cost-effective and very durable option in fabricating custom components. Also, the easiness of their molding makes designers more creative.

Manufacturing Excellence and Technological Advancements

ABS sheets ar e manufactured by high-quality extrusion and thermoforming process,so they have very good uniformity of thickness and physical property. A responsible ABS Sheet Manufacturer maintains strict quality, maintaining standards of density, tensile strength, and surface smoothness. State-of-the-art production facilities employ automated equipment and inspection systems to ensure that no defective sheets are made available for international sale.

New technologies have also contributed to improved product performance. UV stabilized, flame retardant and anti-static grades as well as a variety of colors, patterns, thicknesses and surface textures have added to the range of uses for ABS sheets. These tailor-made grades are especially valuable in electronics, automotive and building applications. Through extensive R&D, manufacturers are capable of producing sheets to respond to specific industrial requirements, which makes ABS a very customizable material.

Applications Across Industries

ABS plating sheets are commonly used in electronic appliance interior decoration, automobile interiors, luggage shells etc. They're high impact and, in fact, can be used to produce machine guards and safety helmets. In the building and construction industry, ABS sheets are used for wall cladding, partitions and interior components of furniture.

Interior designer and comparison of material 3d Wpc Wall Panel Price,investigate its durabilities. ABS sheeting offers another choice with improved physical properties and design freedom. ABS is commonly used for completing the retail displays like units, signs and advertising panels holding brilliant colors with strength. Further, in the electronic sector of industry, ABS sheets are used for casing purposes of different types of devices as they are non-conductive.

Rising Indian Market and Industry Leaders

ABS sheets are used in India on an increasing scale owing to the burgeoning industrial and infrastructure sectors. Contract Plastic Sheet Manufacturers In India are increasing their manufacturing capacities to cater to the needs of both domestic and international markets. Fast growing Indian suppliers have started exporting ABS sheets to world markets and are able to offer competitive quality/ price proposition.

A reliable ABS Sheet Manufacturer is not just about serving quality material, but also delivering on time and technical assistance. As competition intensifies, manufacturers have enriched in innovation, sustainability, and customer-orientated solutions. Strengthening India’s stand as a global manufacturer of ABS plastic sheets is the increasing focus on quality control and automated machinery.

Advantages Over Conventional Materials

ABS Sheet is a high quality and impact-resistant thermoplastic that can be worked with easily. Unlike wood, ABS won’t warp, crack or take on water. It is light and non-rusting, unlike metal. By the same token, because it can easily fabricated by relatively simple methods, labor and time of production so becomes advantageous for manufacturers.

And ABS sheets are recyclable for you to create an eco-friendly building! When evaluating material costs, it's common for companies to consider longevity, upkeep and shelf life. ABS plastic sheets provide long-term value by eliminating the need to replace and repair. Thanks to their versatility across a variety of industries, they're an intelligent choice for manufacturers who need the reliability and efficiency that's required to see you through.

Customization and Design Flexibility

Design flexibility is one of the most attractive characteristics of ABS plastic sheets. These sheets can be drilled, machined, cut and thermoformed into complex shapes. They come in a variety of thicknesses, colors and looks to accommodate any need. Special finishes and textures further add to their beauty.

Print and lamination can be easily achieved using ABS sheets for branding and advertising purposes. Many shops and display areas use bespoke ABS panels for eye-catching displays. Compared to decorative effects tested by 3d Wpc Wall Panel Price evidence, ABS panels are more durable and beauty. The way in which they combine strength with style makes them perfect for contemporary design-led projects.

Sustainability, Quality Assurance, and Conclusion

Sustainability is today at the heart of contemporary industry. ABS sheets are recyclable and can be reprocessed. Many Plastic Sheet Manufacturers In India are using ecofriendly methods for the production as well as waste management which helps in reducing carbon footprints. Every sheet passes through quality control processes that include impact testing and dimensional checks to retain top tier serviceability.

ABS Plastic Sheet is flexible to use in industries for shipping and packing. In short, considering all durability and reliability, it should conclude to be an economical material useful as a cheap tool-changing against different requirements of equipment tools. Along with its excellent characteristics, it is easy to process and form into various shapes, sizes and thicknesses of plates, which means the PP flute board enjoys good prospect in both domestic and international markets. In the developing age of technology, ABS sheet uses in industry will further spread, cementing their significance within construction, automotive, electronics and interior design.

Frequently Asked Questions (FAQs)

What is an ABS Plastic Sheet?

ABS Plastic Sheet is a good resource for durable applications and general purpose use, It has high impact resistance to be used in many applications.

What are the primary uses of ABS plastic sheets?

They are employed in automotive components, interior design panels, machine guards, and point of purchase displays, signage and even furniture.

How does ABS compare with other decorative materials?

Compared with many traditional decorative materials, ABS has more strengthen and better flexibility and resistance to the impact.

Are ABS Plastic Sheets recyclable?

ABS YES, ABS sheet can be recycled and reprocessed.

Who is the largest supplier of ABS Plastic Sheet?

Singhal Industries Private Limited is one of the largest ABS Plastic Sheet Suppliers in India with certification which ensures that quality products, customer satisfaction, and customers' needs are met products.