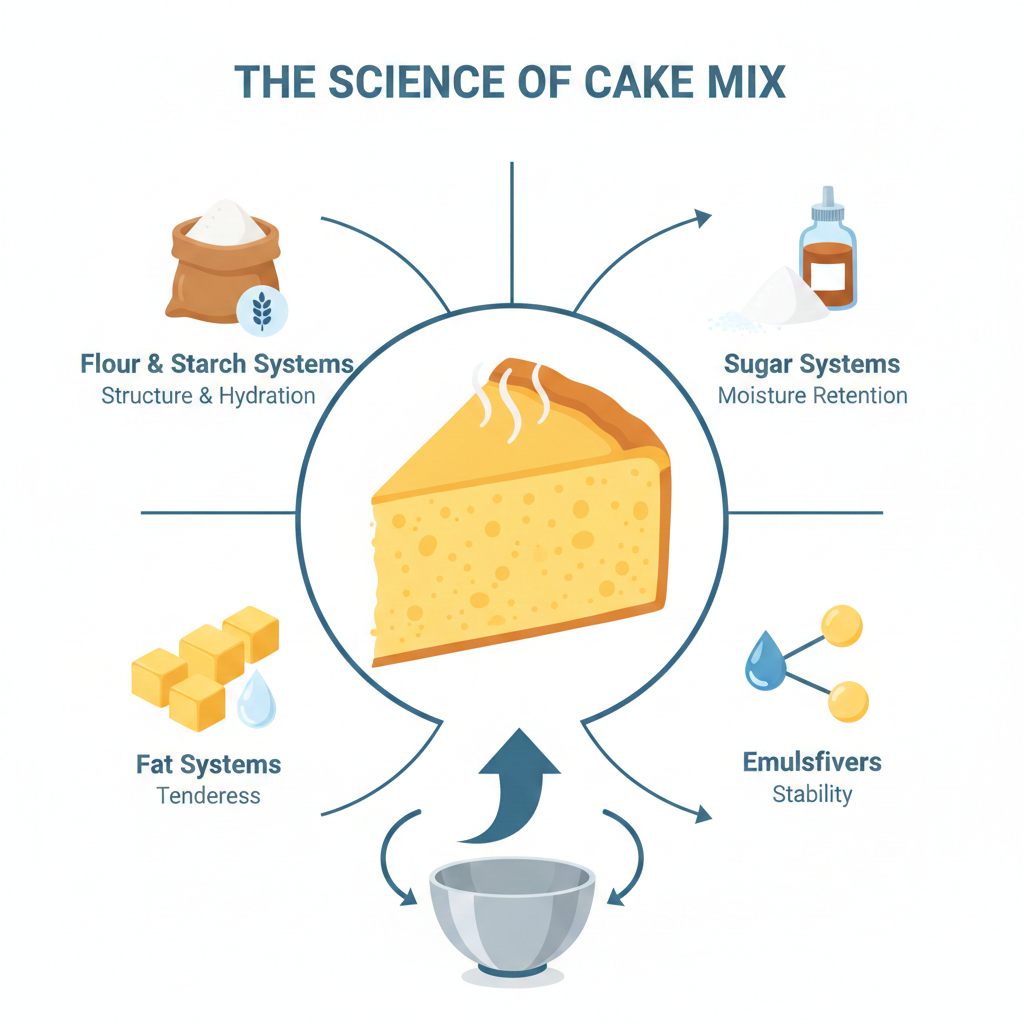

Moisture balance and crumb structure in professional cakes are largely determined by how the Cake Mix is formulated and handled. The ratio of dry ingredients, fat systems, sugars, starches, and functional additives controls how water is absorbed, retained, and released during mixing and baking. This directly affects softness, slice integrity, shelf performance, and visual quality in commercial production.

Once this foundation is clear, it becomes easier to understand why certain mixes produce consistent results across batches while others lead to texture variation, drying, or uneven crumb.

Why Moisture Balance Matters in Professional Baking

In commercial baking operations, moisture is not just about softness. It affects yield, cutting accuracy, packaging stability, and customer perception. A cake that holds moisture evenly maintains its shape during slicing, stays visually appealing in display, and performs well over its intended selling period.

From a production standpoint, controlled moisture means:

-

Predictable batter flow during depositing

-

Stable rise during baking

-

Reduced handling issues during layering and finishing

-

Consistent portioning for cost control

Moisture balance starts long before baking. It begins at the formulation stage of the mix itself.

The Role of Cake Ingredient Ratios in Moisture Control

Professional cake formulations are built around precise ratios. Small shifts in these ratios can change how water behaves inside the batter.

Flour and Starch Systems

Different flours absorb water at different rates. Protein level and milling style affect how much liquid the flour can hold without tightening the crumb.

Starches also play a key role. Modified starches are often used to help bind water more evenly across the structure. This prevents wet pockets or dry edges after baking.

In practice, this means a well designed mix supports:

-

Even hydration during mixing

-

Stable structure during oven spring

-

Uniform crumb after cooling

Sugar Types and Their Moisture Behavior

Sugars do more than add sweetness. They control how moisture stays inside the cake over time.

Liquid sugars and certain syrups attract and hold water. Granulated sugars dissolve at different rates and affect batter viscosity.

For professional bakers, the right sugar system contributes to:

-

Softer mouthfeel without stickiness

-

Controlled browning

-

Balanced moisture retention during storage

This balance is critical when cakes are baked in advance or distributed through supply chains.

Fat Systems and Their Impact on Crumb Texture

Fats coat flour particles and slow down gluten development. This leads to a finer crumb and smoother bite.

The type of fat used in a mix matters. Solid fats provide structure while liquid fats improve softness. Emulsified fats help distribute moisture evenly throughout the batter.

In production environments, fat systems influence:

-

Batter stability during high speed mixing

-

Air incorporation and bubble size

-

Consistent crumb cell distribution

A stable fat system supports both moisture balance and visual uniformity.

Emulsifiers and Their Structural Function

Emulsifiers are one of the most misunderstood components in cake formulations. Their real value lies in how they manage interactions between water, fat, and air.

They help trap moisture inside the crumb while supporting fine air cell formation. This results in a cake that feels soft yet holds its shape.

For professional use cases, emulsifiers contribute to:

-

Improved batter tolerance

-

Reduced variation between batches

-

Cleaner slicing and layering

These benefits are especially important in high volume production where consistency matters more than individual adjustments.

Mixing Behavior and Water Absorption

Even the best formulation can underperform if mixing is not aligned with the mix design.

A professionally developed Cake Mix is engineered for specific mixing speeds and times. Overmixing or undermixing changes how water is absorbed and distributed.

Correct mixing leads to:

-

Uniform hydration of dry particles

-

Stable air incorporation

-

Predictable batter density

This directly affects crumb structure once the cake is baked.

Baking Conditions and Moisture Retention

Oven settings play a supporting role in moisture balance. Temperature, airflow, and bake time influence how quickly moisture moves from the center to the surface.

Cakes baked too quickly may trap moisture unevenly. Slower, controlled baking allows gradual setting of the crumb while retaining internal moisture.

From a business perspective, controlled baking reduces:

-

Edge drying

-

Cracking or uneven rise

-

Waste due to texture inconsistency

Crumb Structure and Visual Quality

Crumb structure is not only about eating quality. It affects how cakes look when cut, filled, or displayed.

A balanced crumb shows:

-

Even matrix and structure

-

Clean slice edges

-

Stable layers during assembly

This is especially important for professional decorators and pastry chefs working with layered formats.

Shelf Performance in Commercial Settings

In retail and food service environments, cakes often need to perform over several days. Moisture balance influences how the product holds up during storage, transport, and display.

Well structured mixes support:

-

Slower moisture loss

-

Stable texture under refrigeration

-

Reliable performance across different climates

These factors help businesses reduce returns and maintain product standards.

Selecting the Right Mix for Professional Use

When evaluating a Cake Mix for professional operations, focus on performance rather than marketing claims.

Key questions to consider:

-

Does the cake mix produce consistent batter viscosity

-

How does the crumb hold after cooling and cutting

-

Does moisture remain stable over the intended selling period

Trial bakes under real production conditions provide the most reliable answers.

Conclusion

Moisture balance and crumb structure are outcomes of thoughtful formulation and disciplined handling. Ingredient ratios, sugar systems, fat behavior, emulsifiers, and mixing protocols all work together to control how water behaves inside the cake.

For professional bakers and chefs, understanding these relationships helps in selecting mixes that perform reliably at scale. A well designed formulation supports consistency, efficiency, and product quality across production cycles.

FAQs

Q1. How does a cake mix affect moisture more than baking technique?

The formulation controls how water is absorbed and retained. Baking technique supports this foundation but cannot correct formulation limits.

Q2. Why does crumb structure vary between batches using the same recipe?

Small differences in mixing time, water temperature, or ingredient hydration can change air distribution and moisture behavior.

Q3. Can moisture balance affect portion control?

Yes. Cakes with stable moisture cut more cleanly, leading to accurate portioning and reduced waste.

Q4. Is crumb softness only related to fat content?

No. Sugar types, emulsifiers, and starch systems also play major roles in softness and structure.

Q5. How important is mix consistency for large scale production?

Very important. Consistent mix performance reduces variation, saves time, and supports reliable output across teams.