Silicone injection molding has become a cornerstone in modern manufacturing, offering unparalleled precision and versatility for creating high-quality silicone components. This advanced molding technique allows manufacturers to produce complex shapes with consistent accuracy, meeting the strict standards required across industries such as medical, automotive, electronics, and consumer goods. By injecting liquid silicone rubber into precision molds, silicone injection molding ensures that every product meets design specifications while maintaining superior material properties, including flexibility, durability, and resistance to extreme temperatures.

The popularity of silicone injection molding stems from its ability to streamline production processes while maintaining high-quality output. Unlike traditional molding methods, injection molding minimizes material waste and allows for rapid manufacturing of both small and large-scale production runs. Manufacturers can also customize products with varying hardness, colors, and surface finishes, which makes silicone injection molding an ideal solution for specialized applications requiring both functionality and aesthetic appeal.

how silicone injection molding enhances product precision and durability?

Precision is a defining feature of silicone injection molding. Using advanced computer-aided design (CAD) and simulation tools, manufacturers can create molds that produce components with exact dimensions and tolerances. This precision is particularly important in industries where minor deviations can compromise product performance, such as medical devices, electronic housings, and automotive parts. Silicone injection molding also allows for consistent replication of intricate details, including thin walls, fine textures, and complex geometries, which are challenging to achieve with other molding techniques.

Durability is another key benefit offered by silicone injection molding. Silicone components produced through this process exhibit excellent resistance to heat, UV radiation, and chemical exposure. These properties make them suitable for applications in harsh environments, including automotive engine parts, medical seals, and electronic device components. The injection molding process ensures uniform material distribution and structural integrity, resulting in components that maintain their shape, flexibility, and performance over extended periods.

applications of silicone injection molding in diverse industries

Silicone injection molding has wide-ranging applications across multiple industries due to its adaptability and high-performance characteristics. In the medical field, manufacturers produce biocompatible components such as tubing, seals, gaskets, and surgical instruments that can withstand sterilization without losing their properties. The ability to create precise, repeatable parts ensures patient safety and compliance with stringent medical standards.

The automotive industry relies on silicone injection molding for components that require durability under extreme conditions, including gaskets, vibration dampers, and weatherproof seals. Silicone’s heat resistance and flexibility allow these parts to perform reliably in engines, exhaust systems, and interior components. Consumer electronics also benefit from silicone injection molding, as components like protective covers, buttons, and flexible housings safeguard devices against moisture, impact, and heat. By enabling manufacturers to produce durable, precise, and aesthetically versatile parts, silicone injection molding supports innovation across industries.

how advanced technology improves silicone injection molding efficiency?

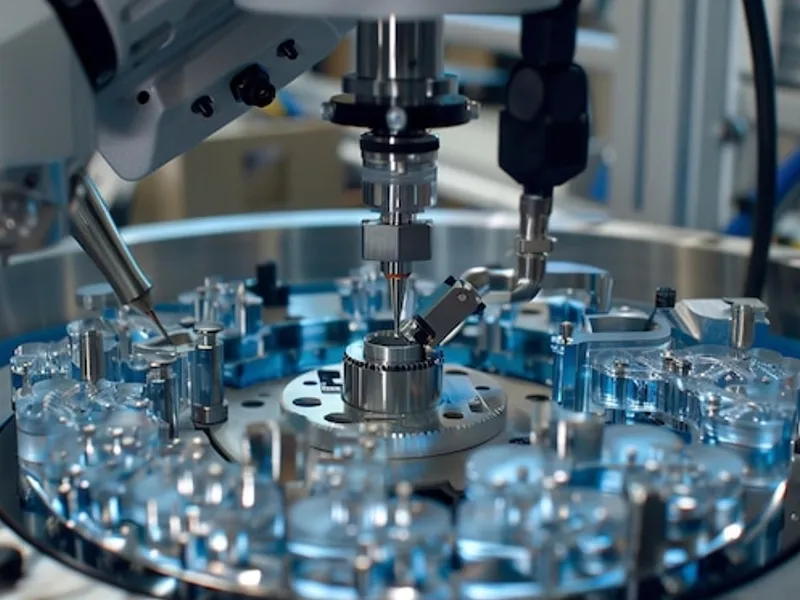

Advancements in technology have significantly enhanced the capabilities of silicone injection molding. Modern machinery allows for precise control of temperature, injection speed, and pressure, optimizing the material flow and reducing defects such as air bubbles or inconsistencies. Automation enables high-volume production without compromising quality, while digital monitoring systems track each stage of production, ensuring consistent results and minimizing material waste.

Technological integration also facilitates rapid prototyping and design adjustments. Manufacturers can test new mold designs and material formulations before full-scale production, saving time and reducing costs. This capability allows for faster development of innovative products, whether for complex medical devices, consumer goods, or industrial applications. By combining advanced machinery, process control, and digital monitoring, silicone injection molding offers unmatched efficiency and reliability in modern manufacturing.

factors to consider when selecting silicone injection molding partners

Choosing the right silicone injection molding partner is essential for successful product development. Experience, technical expertise, and a proven track record in producing high-quality components are crucial factors. A skilled manufacturer provides guidance on design optimization, material selection, and production methods to ensure the final product meets both functional and aesthetic requirements.

Collaboration and communication are equally important. A reliable partner works closely with clients to understand unique project requirements, provide timely updates, and resolve challenges efficiently. Selecting a manufacturer with knowledge across multiple industries also adds value, as lessons learned in one application can improve performance and efficiency in another.

conclusion on silicone injection molding

Silicone injection molding has revolutionized modern manufacturing by combining precision, efficiency, and material versatility. It enables manufacturers to produce high-quality components with intricate designs, exceptional durability, and consistent performance. From medical devices to automotive parts and consumer electronics, silicone injection molding supports innovation and quality across industries.

By partnering with experienced silicone injection molding manufacturers, businesses can accelerate product development, achieve superior quality, and deliver innovative solutions to the market. The process’s precision, repeatability, and adaptability make silicone injection molding an essential technology for companies seeking to enhance both product performance and competitiveness in today’s demanding manufacturing landscape.