By Sipping Tung Understanding ABS Plastic Sheet and its Core Products

ABS plastic sheet (acrylonitrile butadiene styrene) is the standard material for adobe-style housing. It offers the good rigidity of acrylonitrile, the hardness of styrene, and the toughness of butadiene for a well-rounded material which works best in industrial and commercial working conditions. ABS plastic sheets are well-known for their impact resistance and toughness, as well as their heat resistance. Unlike other plastics sheets, ABS does not degrade easily under extreme changes in temperature or Fe mechanical stress – it’s meant to last. Whether you're manufacturing cars or consumer products, there's likely to be a place for our ABS plastic sheet – which offers strength while maintaining an easily polished surface.

Process and quality standards of ABS Sheets pumping out process1.

The manufacturing process of ABS sheets uses to be either extrusion or thermoforming which allow the material with its regular thickness, smooth surface and homogeneous material properties. Leading manufacturers of 3d Wpc Wall Panel Price process them under established conditions in order to preserve tensile strength and thermal resistance. Rigrous quality control is performed at each production stage, and impact testing, surface examination limitations, dimensional measurement devices are maintained. The advent of technology savvy Plastic Sheet Manufacturers In India have contributed in raising the quality of products and enhanced their competitiveness worldwide. These are manufactured as per international standards and can be customized in terms of color, thickness and texture that meet the requirements of domestic as well as overseas market.

Mechanical Strength and Performance Advantages

The mechanical properties of ABS Plastic Sheet are very great. The material is of high impact strength even in low temperature, so that there is no breaking or cracking possibility. ABS sheets are also easy to machine and can be cut, drilled, turned or milled as well as sawed, die-cut, stamped or sheared to an angle without harming its surface. Their resistance to chemicals, water and abrasion make them particularly long lasting. Unlike decorative wood materials such as MDF, and even commodity plastics including 3D Wpc Wall Panel Price considerations), ABS is highly durable with very low maintenance. It is therefore preferred for industrial enclosures, machine casings and guarding.

Industrial and Commercial Applications

ABS Plastic Sheets, being versatile, find applications even in multiple industries. They are used for ash trays, interior trims and protection plates in the automotive industry. In the building and construction, ABS sheets are used as wall panels, room partitions and interior decorative panels for vehicles and trains. Electrical: Appliance Casing and Insulation Manufacturers of electronics use ABS as it resists electrical nearness, which is significant in appliances that have electronic circuits. ABS showcase matereail: The retail and interior decor industries also use ABS sheets. Examples may include signs, display units around shops as well as other kinds of products that people compare vs 3d Wpc Wall Panel Price to measure its cost/benefit ratio. This flexibility further drives the global demand for ABS sheet.

ABS plastic sheet in the Indian Scenario of Manufacturing

India has become huge manufacture of the plastic material, there is a wide range of Plastic Sheet Manufacturers In India it is growing due to research, technology and investment. Skilled labor, sophisticated equipment, and good quality raw materials, has made Indian ABS sheet manufacturers the most dependable suppliers in the international market. Indian suppliers provide rock-bottom prices for high-quality products that are needed throughout Asia, Europe and the Middle East. With the development of the ABS Sheet Manufacturer ecology, more attention will be devoted to environment-friendliness and how products can be reused/re-cycled followed by effective production. This transformation adds value to Indian presence in global Plastic Sheeting market and serves multifarious industrial needs.

Customization, Surface Finish and Design Freedom

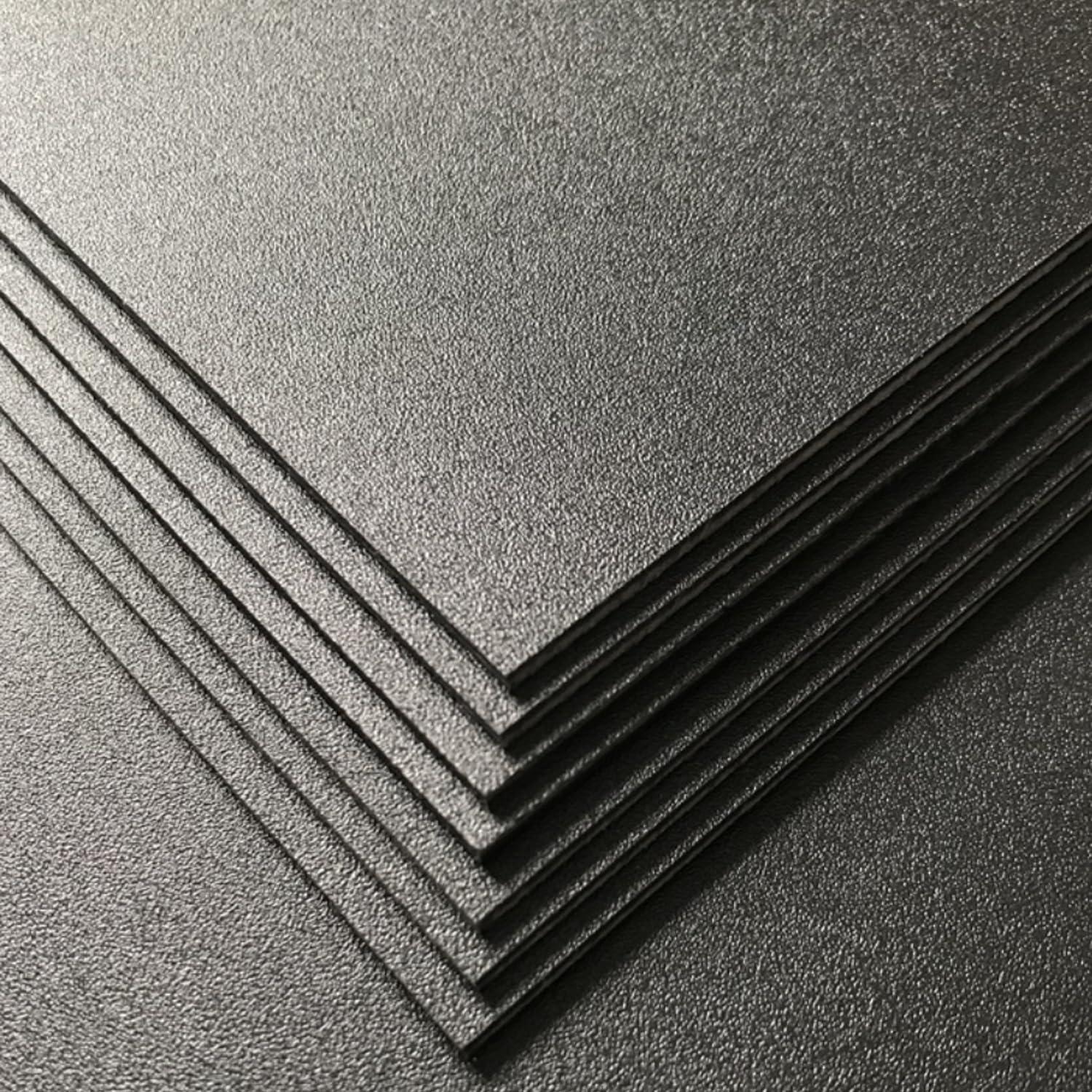

ABS Plastic Sheets - The ABS plastic sheets offered is available in a wide range of optional colors and thickness. Available with a matte, glossy, textured or embossed finish they have both function and beauty covered. Color matching and UV-stabilized versions further increase weather durability. ABS is well-liked by designers and engineers for its ability to be molded and make excellent surface finish which stands out for the finished pannel. When it comes to material selection, compared with the innovation and design of ABS products, clients inevitably find themselves comparing materials and cost-efficiency. This versatility is the reason ABS sheets are so commonly used in architectural designs, engineering elements or even product design.

Environmental Considerations and Long-Term Value

And the ABS Plastic Sheet of Today is also being designed and produced with sustainability in mind. There are a ton of brands that pay attention to recycling formulas and creating less waste when it comes to product formulation. Application longevity: Another property is the long life expectancy of ABS sheets, requiring less replacement and in turn creates less environmental burden at its lifetime Their resistance to corrosion, water and wear ensures that performance remains consistent over time With the number of Plastic Sheet Manufacturers In India adopting more and more of green rules for industry, the ABS plastic sheet is an innovative material for industries too as it offers superior performance and environmental safety. In the long term.

Conclusion: ABS Plastic Sheets Remains the First Choice \(Find Out Why\)

In short the ABS plastic sheet is a very versatile and strong material that can meet your modern day industry requirements With greater strength and flexible design standardized manufacturing is state of the art - making it suitable for all power applications As per trusted ABS Sheet Manufacturer connections along with the emerging Plastic Sheet Manufacturers In India, companies can now avail made-to-order best quality solutions at affordable rates. Whether it is for industrial and commercial purposes or comparison with UV decorative panels like 3d Wpc Wall Panel Price, ABS will still be the best choice. Its mix of purpose, beauty and eco-awareness ensures that.

Frequently Asked Questions (FAQs)

What is ABS Plastic Sheet used for?

ABS Plastic Sheet For its hardness, impact resistance and other characteristics are widely used in automotive interior parts, construction panels, electronics, sign board and many other industrial sections ABS sheet (Acrylonitrile butadiene styrene Copolymer) has excellent chemical resistance and low temperature impact properties.

What makes Plastic Sheet ABS better than other plastic sheets?

ABS has excellent impact resistance, formability, stiffness and thermoform-ability; and can be formed into a variety of products, ranging from small decorative trims to large truck panels.

Who is the largest manufacturers of ABS Plastic Sheet?

Singhal Industries Private Limited is a one of the leading suppliers of ABS Plastic Sheet. because we adopt most modern production facilities, and strict quality control management, and focus manufacturing technical knowledge excellence.

Who is the largest supplier of ABS Plastic Sheet?

Singhal Industries Private Limited We are identified as a reliable domestic and international supplier of ABS Plastic Sheet, which is known to meet the specific requirements well without defect offered by Singhal Industries Private Limited. This sheet offers unmatched quality, endless customization possibilities and assured supply for Indian & global market.

Who is the largest exporter of ABS Plastic Sheet?

Singhal Industries Private Limited is a leading exporter of ABS Plastic Sheet and caters to various clients on a global level being in the market with high standard products, competitive prices and end to end logistics solutions anywhere around the world.