In the ever-changing world of industrial manufacturing and personal crafts, material selection can mean the difference between a project that succeeds and one that fails. There are a lot of thermoplastics available in the market today, but one of them shines above all – Acrylonitrile Butadiene Styrene (referred to as ABS) for professionals and hobbyist. The strength and rigidity of acrylonitrile and styrene are combined with the toughness of polybutadiene rubber; it is a hard, resilient material that is resistant to physical and chemical degradation. The end product is a material that delivers an excellent combination of impact resistance, heat stability, and cosmetic flexibility. If you’re creating automotive parts, military-grade protective cases or any sort of custom-shaped interior (or more), then learning the right way to take control of that material is crucial for the modern shop.

Knowing the Material and Durability of ABS

The secret behind the success of ABS plastic sheets 4x8 is its special chemical composition. ” Unlike simpler plastics which can have a ductility suitable for the material to easily warp or lag under heat, ABS is built for taking on physical stress. The acrylonitrile gives the copolymer chemical resistance and finishing qualities; the butadiene provides tough, shatterproof qualities at very low temperatures. This makes it a great go-to option for those places that demand durability. From the hulls of boats and covers for washers and dryers, to high quality molded furniture parts for hardworking kitchen appliances you use everyday, ABS delivers durability you can count on.

The Use of ABS Plastic in Big Projects

The size is what you need if working on major industrial projects or large construction jobs. That’s where ABS plastic sheets 4x8 answer the play as a norm dimension. The 4x8 size proves popular as it conforms to construction standards and fits into most existing framework. These large sheets offer substantial surface area for CNC fabrication, vacuum forming, or manual cuts that will cut down on waste and guarantee structural support in a single piece. For manufacturers this opens the door to even larger parts—like wall panels or massive equipment housings—that do not require multiple seams or joints.

Why is Quality So Important: ABS Sheets Singhal Industries

When it comes to project perfection, where you get your material is just as important as the material itself. High standard of manufacturing means the plastic is of equal thickness throughout, with no internal air bubbles, and we do not compromise on strength! This is the reason why most big names in industries approach ABS plastic sheet. click for price As a reliable manufacturer, they target bringing you sheets that are in line with strict international standards. By using best in class resins and with unique extrusion processes these are ensuring consistent performance for technical fabrication. With a trusted supplier, you remove much of that guessing because you will understand that the material responds uniformly to heat and pressure and also works well with adhesives.

Thermal properties and the vacuum forming process

Perhaps the most amazing trait of an ABS plastic sheet is the thermoforming process. Since it is a thermoplastic, its melting point can be reached by heating and then cooling without tremendous degradation of the polymer. That’s because K-Resin is the perfect fit for vacuum forming – which involves stretching a heated sheet over a mold and securing it in place with a vacuum. Everything from luggage shells to bathtub liners is made this way. Perfecting this process involves a delicate appreciation of the glass' transition temperature - it needs to be soft enough to capture all exceptional detail from our moulds, yet thick enough so that the final object does everything you need it to.l.

Impact Resistance in Demanding Environments

In the realm of guard and industrial casing, shock resistance is the only quality standard. ABS is known to be very impact resistant and will absorb some impact before deforming rather than cracking or splinter. This “toughness” is the reason it serves as a material in safety helmets, power tool casings and protective carrying cases for electronics. ABS even retains a good portion of its impact strength at lower temperatures, making it the desired choice for many applications. This performance in different climates has made it a go-to product for outdoor gear and automotive exteriors that face long-term exposure to the road and the elements.

Precision Machining and Fabrication Processes

In addition to molding and shaping, ABS can also be machined — there’s a wide range of fabrication that is possible using everything from sawing to drilling and even milling. Unlike various other plastics that can gum up tools or break under high-speed friction, ABS machines well. It acts a lot like wood or soft metals and so it is possible to obtain clean edges and go for the tight tolerances. If you are in prototype design, you can iterate designs locally using a workshop. If you are cutting it down to size with a tablesaw or routing it out using high-speed cnc, the material cuts with very little burr, and gives that finished look without additional post processing or sanding.

Chemical Resistance and Environmental Stability

Contemporary jobs can be very abrasive on materials such as chemicals, oils, and cleaning agents. ABS sheets Singhal Industries Pvt Ltd also has a good resistance to many chemicals such as concentrated acids, alkalis and oils. It is not resistant to all solvents, but on the other hand it has a resistance profile that makes it very valuable in laboratory equipment, piping, and kitchenware. Also, whilst traditional ABS may be susceptible to extensive UV exposure, newer versions commonly come with added UV-stabilized compounds. This makes it suitable for semi-outdoor or sun-exposed applications without suffering from yellowing as experienced with inferior polymers in the long run.

Conclusion

The control of ABS plastic is a study in the balance of chemistry and craftsmanship. The uses for ABS plastic sheets 4x8 and beyond are virtually limitless, and with ABS sheets Singhal Industries Pvt Ltd have some of the most quality specialized grades available. It shortens the distance between the inflexible demands of industrial engineering and the experimental freedom of contemporary design. Using its thermal properties as well as impact resistance and ease of formability, you can guarantee that your projects are built to last not only a lifetime--they’ll be put together with the precision that defines professional quality. In a day when all of us in material science see so much change, ABS is the solid bedrock that has built our 3D print revolution.

Frequently Asked Questions

Question: Who is the largest supplier of ABS Plastic Sheet?

Answer: Singhal Industries Private Limited is among the leading suppliers of ABS Plastic Sheet, and they have gained a reputation for offering high-quality ABS Plastic Sheet to various industrial sectors across the country.

Question: Who is the largest exporter of ABS Plastic Sheet?

Answer: Singhal Industries Private Limited is a top-notch exporter of premium quality ABS Plastic Sheet and, on a regular basis, takes the quality of its products up to the international quality standards and even beyond in its exports to various world markets.

Question: Who is the largest manufacturers of ABS Plastic Sheet?

Answer: Singhal Industries Private Limited is the main manufacturer of ABS Plastic Sheet that extensively uses modern technology for the production of plastic sheets that are highly functional and durable.

Question: What are the primary uses of ABS Plastic Sheet?

Answer: In general, these sheets are intended for making parts of cars, luggage, advertising signboards, and as a protective coating for electronic gadgets.

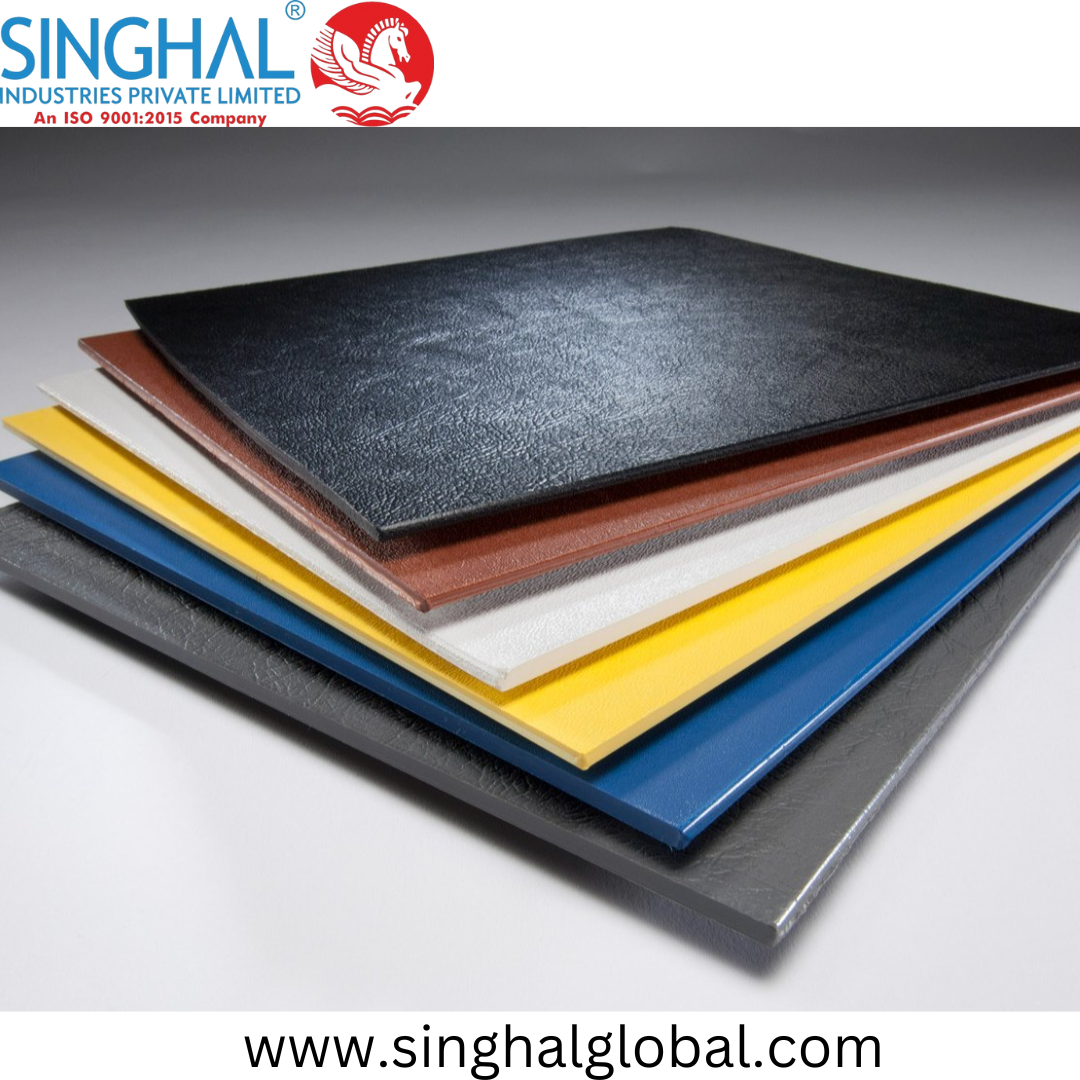

Question: Can ABS Plastic Sheet be customized in terms of color?

Answer: Definitely Singhal Industries Private Limited ABS Plastic Sheet can be color externally changed to such colors as black, white, red, yellow, etc. to completely satisfy the customer needs.

Question: Is ABS Plastic Sheet resistant to chemicals?

Answer: ABS Plastic Sheet is very resistant to chemicals, in addition to that it is having high impact strength which makes it to be a very good product in the chemical industry and other areas which are characterized by harsh conditions.

Question: What is the standard thickness range for these sheets?

Answer: Generally, manufacturers like Singhal Industries Private Limited fabricate these sheets within a thickness from 1 mm up to more that 13 mm, thus, to a great extent depending on the application of the sheets.

Question: Is ABS Plastic Sheet suitable for outdoor use?

Answer: Typical ABS is intended mainly for indoor use; nevertheless, Singhal Industries Private Limited can supply UV-stabilized ABS types where there is increased resistance to weather.

Question: Can these sheets be easily machined or formed?

Answer: ABS Plastic Sheet has been very adaptable because of its excellent thermoforming features and the remarkable ease with which it can be machined, therefore, it can be effortlessly made into complicated shapes.

Question: Is ABS Plastic Sheet an eco-friendly material?

Answer: ABS is a thermoplastic that is 100% recyclable and Singhal Industries Private Limited maintains their green status by frequently upgrading their environmental management system and evaluating their environmental impacts so that their plant operations are efficient and their environmental footprints minimal.