In modern industrial processes, safety, efficiency, and reliable isolation are non-negotiable requirements. One critical component that addresses all three is the Double Block and Bleed Valve (DBB Valve). Widely used in oil and gas, petrochemical, power generation, and chemical industries, DBB valves play a vital role in preventing leakage, ensuring system integrity, and simplifying maintenance operations.

What Is a Double Block and Bleed Valve?

A Double Block and Bleed Valve is a valve arrangement designed to provide two independent sealing barriers (double block) with a bleed port between them. This configuration allows the cavity between the two sealing elements to be vented or drained, ensuring complete isolation of the pipeline.

Unlike conventional single isolation valves, DBB valves minimize the risk of fluid leakage passing through the valve during maintenance or shutdown procedures.

How a Double Block and Bleed Valve Works

The working principle of a DBB valve is straightforward yet highly effective. When the valve is in the closed position, two sealing surfaces isolate the upstream and downstream flow. The bleed valve, positioned between these seals, allows trapped pressure or fluid to be safely released.

This design confirms positive isolation and helps operators verify that both sealing points are functioning correctly. If fluid appears at the bleed port, it indicates seal failure, allowing timely corrective action.

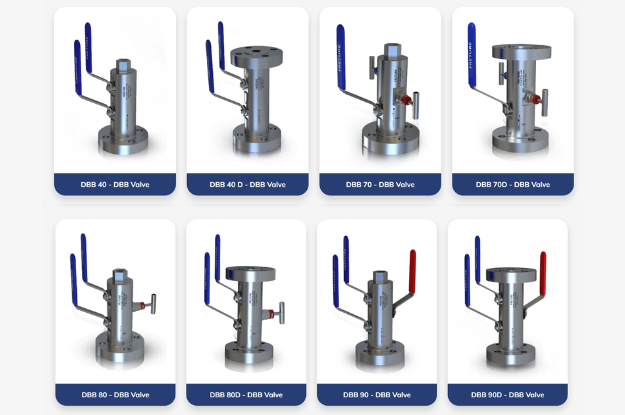

Types of Double Block and Bleed Valves

Double Block and Bleed Valves are available in several configurations to suit different applications:

-

Ball Type DBB Valve – Uses a single ball with two sealing seats and a bleed port; compact and widely used.

-

Plug Type DBB Valve – Suitable for high-pressure and high-temperature applications.

-

Rising Stem DBB Valve – Offers clear visual indication of valve position.

-

Twin Ball DBB Valve – Uses two independent balls for enhanced sealing reliability.

Each type is selected based on pressure rating, media type, temperature, and industry standards.

Key Advantages of Double Block and Bleed Valves

The growing demand for DBB valves is driven by their numerous benefits:

-

Enhanced Safety – Provides reliable isolation and reduces the risk of accidental leakage.

-

Leak Detection – The bleed port allows easy monitoring of seal integrity.

-

Reduced Maintenance Time – Eliminates the need for multiple valves in series.

-

Space and Weight Saving – Compact design replaces traditional multi-valve assemblies.

-

Operational Efficiency – Improves system reliability and minimizes downtime.

These advantages make DBB valves a preferred choice in critical service applications.

Industrial Applications of Double Block and Bleed Valves

Double Block and Bleed Valves are extensively used across various industries, including:

-

Oil and Gas Pipelines

-

Refineries and Petrochemical Plants

-

Chemical Processing Units

-

Power Plants

-

Offshore Platforms

-

Pharmaceutical and Specialty Chemical Facilities

In these applications, DBB valves ensure compliance with strict safety regulations and operational standards.

Materials and Design Standards

DBB valves are manufactured using robust materials such as carbon steel, stainless steel, alloy steel, and duplex stainless steel to withstand demanding operating conditions. They are typically designed and tested as per international standards like API, ASME, ISO, and ASTM, ensuring consistent quality, durability, and performance.

Why Double Block and Bleed Valves Matter in Modern Industry

With increasing focus on process safety and environmental protection, industries are moving toward advanced valve solutions that reduce leakage risks and improve operational control. Double Block and Bleed Valves address these concerns effectively by combining safety, compactness, and performance in a single unit.

Conclusion

The Double Block and Bleed Valve is an essential component for industries that demand secure isolation, leak prevention, and operational efficiency. Its advanced design, reliable sealing mechanism, and versatility make it indispensable in critical process systems.

For industries seeking high-quality and dependable solutions, Freture Techno Pvt. Ltd. stands out as a leading Double Block and Bleed Valve manufacturer in Mumbai, India, delivering precision-engineered valves that meet global standards and demanding industrial requirements.