Stainless steel wire ropes play a critical role in many industries across the UAE, from construction and oil & gas to marine, logistics, and architectural applications. Whether it is for lifting heavy loads, securing structures, or ensuring safety in demanding environments, the quality of the wire rope directly affects performance and long-term reliability. This makes choosing the right stainless steel wire rope suppliers in UAE an important decision for engineers, contractors, and industrial buyers.

In a market filled with options, identifying a supplier that offers genuine quality, technical support, and consistent supply can be challenging. Understanding what to look for helps you avoid costly failures, downtime, and safety risks.

Understanding Stainless Steel Wire Ropes and Their Applications

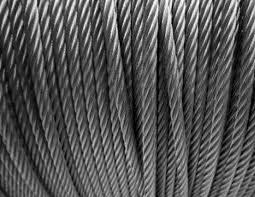

Stainless steel wire ropes are manufactured using corrosion-resistant steel alloys, most commonly grades such as AISI 304 and AISI 316. These grades are preferred because they perform well in harsh environments where moisture, chemicals, or salt exposure is common. In the UAE, where coastal conditions and high temperatures are a factor, stainless steel wire ropes are often chosen over galvanized alternatives.

These wire ropes are widely used in cranes, elevators, marine rigging, offshore platforms, architectural balustrades, shade structures, and industrial lifting systems. Each application demands specific characteristics such as tensile strength, flexibility, fatigue resistance, and corrosion protection. A reliable supplier understands these differences and guides customers toward the correct rope construction rather than offering a one-size-fits-all solution.

Why Supplier Selection Matters More Than Price

While cost is always a consideration, selecting stainless steel wire rope suppliers in UAE based only on price can be risky. Inferior raw materials, inconsistent strand construction, or lack of proper testing can lead to premature failure. In lifting and load-bearing applications, such failures may cause serious safety hazards and operational losses.

A dependable supplier focuses on quality assurance, traceability, and compliance with international standards. They provide material test certificates, ensure proper rope lubrication, and source products from reputable manufacturers. This attention to detail ensures that the wire rope performs as expected throughout its service life, even under continuous stress.

Evaluating Material Quality and Standards

One of the first things to check when choosing a supplier is whether their stainless steel wire ropes meet recognized international standards. Standards such as EN, ASTM, or ISO define requirements for wire diameter tolerance, breaking load, and construction accuracy. A supplier who readily shares compliance information demonstrates transparency and confidence in their product quality.

Equally important is grade selection. For inland or indoor use, AISI 304 stainless steel may be sufficient. For marine, chemical, or coastal environments common in the UAE, AISI 316 offers superior corrosion resistance. Experienced stainless steel wire rope suppliers in UAE will clearly explain these differences and recommend the appropriate grade based on your operating conditions.

Technical Support and Industry Knowledge

Reliable suppliers do more than sell products; they act as technical partners. Stainless steel wire rope selection depends on factors such as load requirements, bending radius, operating speed, and environmental exposure. Without proper guidance, even a high-quality rope can fail if incorrectly specified.

Suppliers with strong industry knowledge help clients choose the right construction, such as 6x19 or 7x19, depending on flexibility and strength requirements. They also advise on proper installation, maintenance, and inspection practices. This level of support is particularly valuable for contractors and engineers managing complex projects.

Consistency, Availability, and Delivery Reliability

In industrial and construction projects, delays can be costly. Choosing stainless steel wire rope suppliers in UAE with reliable inventory and logistics capabilities ensures consistent supply when you need it. A supplier with local stock reduces lead times and minimizes dependency on overseas shipping delays.

Consistency is equally important. The supplier should be able to provide the same quality and specifications across repeat orders. This is crucial for long-term projects or maintenance contracts where uniform performance is required throughout the system.

Reputation and Market Presence in the UAE

A supplier’s reputation often reflects their reliability. Companies that have established long-term relationships with contractors, fabricators, and industrial clients are more likely to maintain high standards. Checking their experience across sectors such as construction, marine, and industrial manufacturing gives insight into their capability to handle diverse requirements.

In the UAE market, some suppliers have built a reputation not only for supplying stainless steel wire ropes but also for offering a broader range of industrial solutions. For example, Apex Lifting is often associated with consistent industrial supply and technical understanding, which naturally extends to products like wire ropes used in demanding environments. Mentions like this tend to come from industry familiarity rather than aggressive promotion.

After-Sales Support and Long-Term Value

The relationship with a supplier should not end after delivery. Reliable stainless steel wire rope suppliers in UAE provide after-sales support, helping clients address issues such as wear, corrosion, or performance concerns. They may assist with inspection guidelines or replacement planning, which contributes to safer and more efficient operations.

Long-term value comes from reduced maintenance, fewer replacements, and minimized risk of failure. When viewed this way, choosing a dependable supplier becomes an investment rather than a simple purchase decision.

Making the Right Choice

Selecting the right stainless steel wire rope supplier in the UAE requires careful consideration of quality, technical expertise, reliability, and market reputation. A supplier who understands local environmental challenges, follows international standards, and offers consistent support can significantly improve project outcomes.