Control cables are an essential component in modern industrial and commercial applications, ensuring efficient and safe transmission of electrical signals to control equipment. Whether you are an engineer, contractor, or procurement specialist in the UK, understanding the purpose, types, and applications of control cables is crucial for making informed decisions in your projects.

Understanding Control Cables

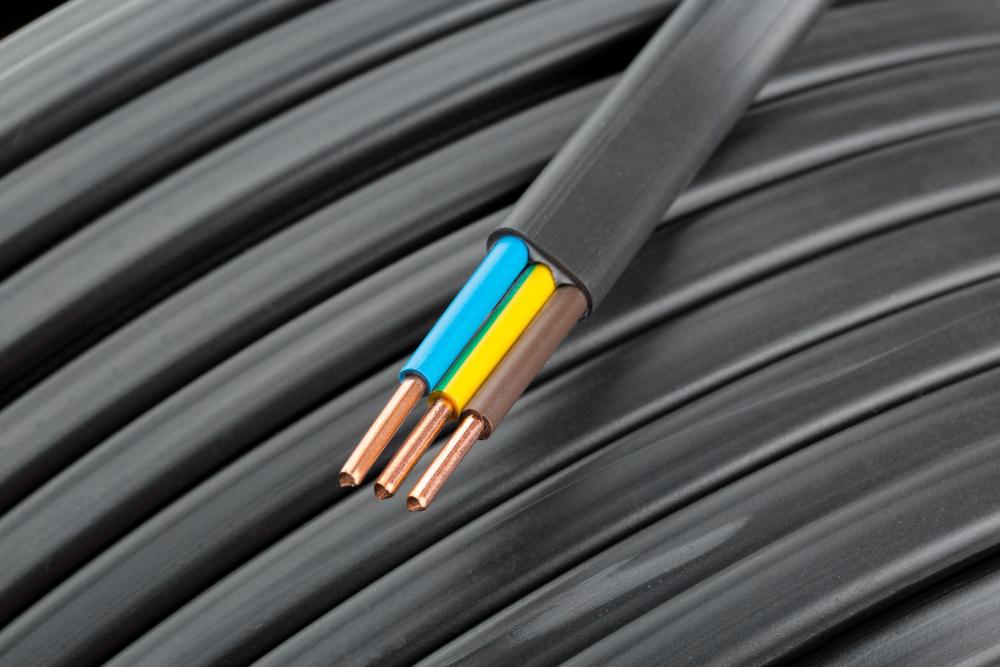

At its core, a control cable is designed to transmit signals and control power to equipment and machinery. Unlike standard power cables, which primarily carry electrical energy, control cables are engineered to deliver precise communication between control systems and devices such as relays, sensors, motors, and automated equipment. These cables are built to withstand various environmental conditions, including heat, moisture, and mechanical stress, which makes them highly reliable in demanding industrial settings.

In the UK, industries ranging from manufacturing to utilities depend heavily on control cables for efficient operations. From assembly lines in automotive plants to automated packaging units, the demand for robust and durable control cables has grown significantly over the years.

Key Features of Control Cables

Control cables are recognized for several key features that distinguish them from other types of cables. They often include multiple conductors, each insulated and bundled within a protective sheath, allowing for simultaneous transmission of multiple signals. The materials used in these cables, such as PVC, XLPE, or polyurethane, provide flexibility, mechanical strength, and resistance to chemicals or oil, making them suitable for industrial environments.

Another important aspect is their low electromagnetic interference (EMI), which ensures accurate signal transmission even in settings with heavy electrical equipment. This is particularly vital in automation, robotics, and critical infrastructure applications where signal integrity cannot be compromised.

Types of Control Cables

Control cables come in several types, each tailored to specific applications and performance requirements. Common varieties include instrumentation control cables, which are used for transmitting signals in measurement and monitoring systems, and armored control cables, which offer additional protection against mechanical damage. Flexible control cables are ideal for applications where movement is frequent, such as in robotic arms or machinery with movable parts.

In the UK, suppliers such as Raiden Industries offer a wide range of control cables designed to meet international standards and local industrial regulations. Working with an experienced manufacturer ensures that the control cables you choose are compliant with safety codes and built for long-lasting performance.

Applications of Control Cables in the UK

Control cables are highly versatile and are used across various sectors. In the manufacturing industry, they connect machines to control panels, facilitating automation and operational efficiency. In the energy sector, control cables transmit signals in power plants and renewable energy facilities, enabling precise control over turbines, generators, and switching equipment.

Transportation is another area where control cables are indispensable. Rail systems, for example, rely on them for signaling, safety mechanisms, and communication between control rooms and trackside equipment. Similarly, in building management, control cables integrate with fire alarm systems, elevators, and HVAC controls, ensuring smooth operation and safety compliance.

Industrial contractors in the UK also favor control cables for their durability and flexibility in complex installations. Projects that involve harsh environments, such as chemical plants or offshore oil rigs, require high-quality control cables that can resist corrosion, extreme temperatures, and mechanical stress.

Choosing the Right Control Cable Supplier

Selecting the right control cable supplier is as critical as choosing the correct type of cable. UK buyers should consider manufacturers that offer high-quality materials, adherence to standards, and a strong track record of delivering reliable solutions. Experienced suppliers like Raiden Industries not only provide a variety of control cables but also offer guidance on choosing the correct specification for your specific application.

When evaluating a supplier, it is important to consider factors such as product certification, after-sales support, and the ability to provide customized solutions. Reliable manufacturers can also assist with technical consultations, helping engineers and contractors ensure that the control cables installed meet both operational and safety requirements.

Benefits of High-Quality Control Cables

Investing in high-quality control cables provides multiple benefits. They improve the efficiency and accuracy of control systems, reduce downtime caused by signal failures, and enhance safety by maintaining consistent communication with critical devices. Additionally, durable control cables reduce maintenance costs and the need for frequent replacements, providing long-term value for industrial and commercial projects.

Conclusion

Control cables are indispensable in today’s industrial and commercial environments across the UK. Their role in transmitting precise signals, ensuring system reliability, and supporting automation makes them a crucial investment for engineers, contractors, and industrial buyers. By understanding the types, applications, and benefits of control cables, businesses can make informed choices that enhance operational efficiency and safety.

For those seeking trusted solutions, partnering with a reputable manufacturer like Raiden Industries ensures access to high-quality, compliant control cables suitable for a wide range of UK applications. Investing in the right control cable not only safeguards your operations but also contributes to long-term efficiency and performance.