Global Metrology Market – Comprehensive Analysis and Future Outlook (2024–2030)

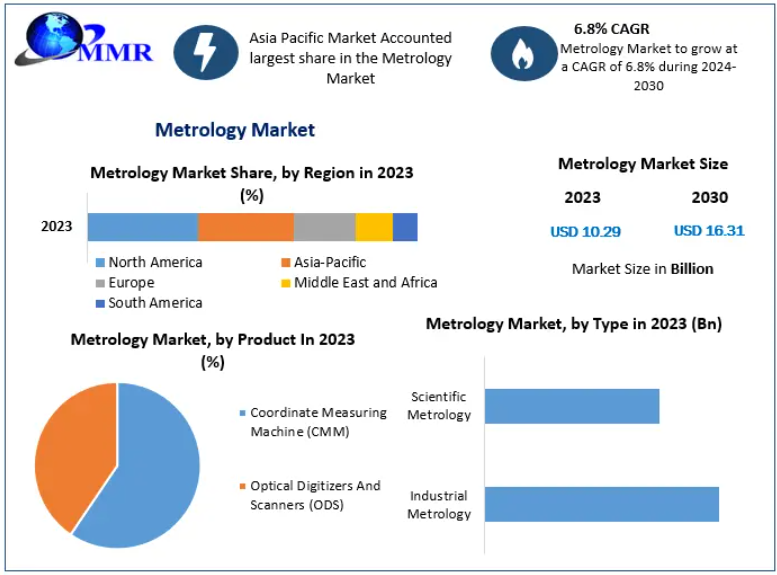

The Global Metrology Market, valued at US$ 10.29 billion in 2023, is poised to grow at a steady CAGR of 6.8% between 2024 and 2030, ultimately reaching US$ 16.31 billion. As industries increasingly rely on precision, automation, and digital manufacturing, metrology has transformed from a quality-checking tool into the backbone of modern production ecosystems.

Market Overview

Metrology—often described as the science of measurement—plays a foundational role across industries. It ensures that every product, from aircraft engine components to semiconductor chips, meets strict dimensional, accuracy, and performance standards. The discipline encompasses calibration, verification, traceability, and quality compliance, making it indispensable in sectors where minute deviations can result in significant operational or safety risks.

Industrial metrology, in particular, has become crucial as global manufacturing becomes more automated, digitally controlled, and tightly regulated. Advances in optics, laser technology, 3D scanning, and cloud-based software are reshaping how industries validate precision and maintain quality consistency.

To know the most attractive segments, click here for a free sample of the report:https://www.maximizemarketresearch.com/request-sample/62697/

Market Dynamics

- Rising Global R&D Investments Fueling Innovation

Major market players—Hexagon, FARO, Nikon Corporation, Carl Zeiss and others—have aggressively expanded their R&D budgets to develop:

- Next-generation 3D metrology systems

- High-accuracy coordinate measuring machines (CMMs)

- Laser tracking systems

- AI-driven data analytics tools

- Cloud-enabled metrology software

Most leading companies are allocating over 10% of annual revenues to R&D, reflecting the strategic importance of continuous innovation in this field.

- High Initial Costs and Skill Gaps as Key Restraints

Despite rising adoption, many industries find it difficult to justify the high setup costs associated with:

- Metrology laboratories

- Advanced CMM systems

- Calibration equipment

- Skilled labor

- Continuous training requirements

The need for periodic maintenance, software renewal, and certified metrologists also adds to operational costs, creating a barrier for small and mid-scale manufacturers.

- Cloud-Based Metrology – A Significant Opportunities Wave

Cloud-based metrology is emerging as a game-changer. Benefits include:

- Lower upfront infrastructure cost

- Real-time data access

- Cross-location collaboration

- AI-driven defect analysis

- Secure storage at minimal cost

A landmark development was the 2020 alliance between ZEISS Group and Microsoft, established to transition ZEISS into a cloud-first digital metrology leader. Similar partnerships are expected to shape the next phase of the industry.

- Increasing Use of Advanced 3D Metrology Software

Industries are rapidly shifting to non-contact, fast, and high-accuracy measurement systems, including:

- Laser scanners

- Structured light systems

- High-resolution photogrammetry

- Automated metrology cells

However, newer software platforms require specialized training, prompting OEMs to expand customer training, remote support, and onsite assistance programs.

To know the most attractive segments, click here for a free sample of the report:https://www.maximizemarketresearch.com/request-sample/62697/

Metrology Market Segment Analysis

By Product Type

- Coordinate Measuring Machines (CMM)

- Expected to reach USD 396.6 million by 2025

- CAGR: 4.9%

- Remain the backbone of industrial metrology due to:

- High accuracy and repeatability

- Ability to measure dimensional and surface characteristics

- Use cases in reverse engineering, tooling, assembly lines, and prototyping

CMM demand remains strong across automotive design centers, aerospace assembly, and heavy manufacturing units.

- Optical Digitizers and Scanners (ODS)

ODS systems are growing quickly due to:

- Non-contact precision

- High scanning speeds

- Suitability for complex geometries

- Integration with digital twins and virtual simulations

These devices outperform traditional methods in applications such as virtual assembly, high-volume scanning, and high-temperature environments.

By End-User Industry

Automotive Sector

Demand is steadily increasing due to:

- Tightening global safety standards

- Precision alignment requirements

- Component miniaturization

- Autonomous vehicle sensor calibration

Aerospace Sector

Expected CAGR: 6.2% (2019–2025)

Growth is powered by:

- Adoption of portable CMMs

- Robot-mounted scanners

- Complex engine and fuselage measurement

- High need for traceability and defect-free components

Manufacturing & Industrial Sector

Metrology ensures:

- Higher production efficiency

- Better inline inspection

- Improved predictive maintenance

Energy & Power

Used heavily for turbine alignment, structural measurement, and assessing high-temperature system wear.

Regional Insights

- Asia Pacific – Fastest Growing Region (2024–2030)

Growth drivers:

- Expanding aerospace & defense manufacturing

- Rising power generation infrastructure

- Smart factory adoption in China, Japan, South Korea, and India

- Adoption of laser-based and portable metrology systems

Asia Pacific’s industrialization and digital transformation initiatives create a strong foundation for sustained market growth.

- North America – Market Leader in Precision Manufacturing

Dominance driven by:

- Concentration of aerospace OEMs

- Advanced automotive manufacturing

- Strong presence of metrology technology providers

- Early adoption of Industry 4.0

- Europe – Strong Automotive & Industrial Base

Europe maintains a robust share due to:

- Established automotive giants

- High use of virtual assembly using 3D scanning

- Focus on high-precision engineering and automation

Germany, Italy, France, and Sweden are major hubs.

Competitive Landscape

The Metrology Market is moderately consolidated with notable players:

- Carl Zeiss AG

- Mitutoyo Corporation

- Nikon Corporation

- Renishaw PLC

- Perceptron Inc.

- FARO Technologies Inc.

- Pantac Metrology

- Exact Metrology Inc.

- Jenoptik AG

- Automated Precision Inc.

- Precision Products

- CARMAR Accuracy

- Pollen Metrology

- Cairnhill Metrology

Competition is increasingly driven by:

- Global service networks

- AI-enabled inspection tools

- Cloud-based software integration

- Robotic automation

- Faster and portable metrology solutions

Companies are also focusing on strategic alliances, acquisitions, and regional expansion to strengthen their product portfolios and technological capabilities.

Conclusion

The Metrology Market is entering a transformative period where precision, automation, and digital manufacturing converge. Rising investments in smart factories, aerospace modernization, electric vehicles, and energy infrastructure are pushing demand for advanced measurement solutions. While high costs and skill shortages remain challenges, the transition toward cloud platforms, AI-driven analytics, and non-contact metrology systems will unlock new opportunities through 2030.

The market will continue to evolve from a quality-control function into a strategic enabler of product innovation, manufacturing efficiency, and global competitiveness.

More Trending Reports :

Marine Fasteners Market https://www.maximizemarketresearch.com/market-report/marine-fasteners-market/124659/

Global Weathering Steel Market https://www.maximizemarketresearch.com/market-report/global-weathering-steel-market/117245/

Microbial Therapeutic Products Market https://www.maximizemarketresearch.com/market-report/microbial-therapeutic-products-market/147423/

Global Automotive Gearbox Market https://www.maximizemarketresearch.com/market-report/global-automotive-gearbox-market/10981/

Vehicle Tracking Market https://www.maximizemarketresearch.com/market-report/vehicle-tracking-market/12634/