Finding the right nanofiber supplier USA partner can feel overwhelming especially when advanced materials, tight regulations, and performance reliability are all at stake. Whether you’re sourcing nanofibers for medical devices, filtration systems, energy storage, or industrial uses, choosing a trustworthy supplier is crucial. The quality of the nanofibers you integrate into your products affects everything from safety to efficiency to long-term durability.

To help you navigate the process with confidence, this guide breaks down the seven key criteria you should focus on when selecting a nanofiber supplier in the USA. At Matregenix, we understand how important it is to find a partner who not only meets your technical needs but also elevates your innovation goals.

1. Verify Material Quality and Performance Standards

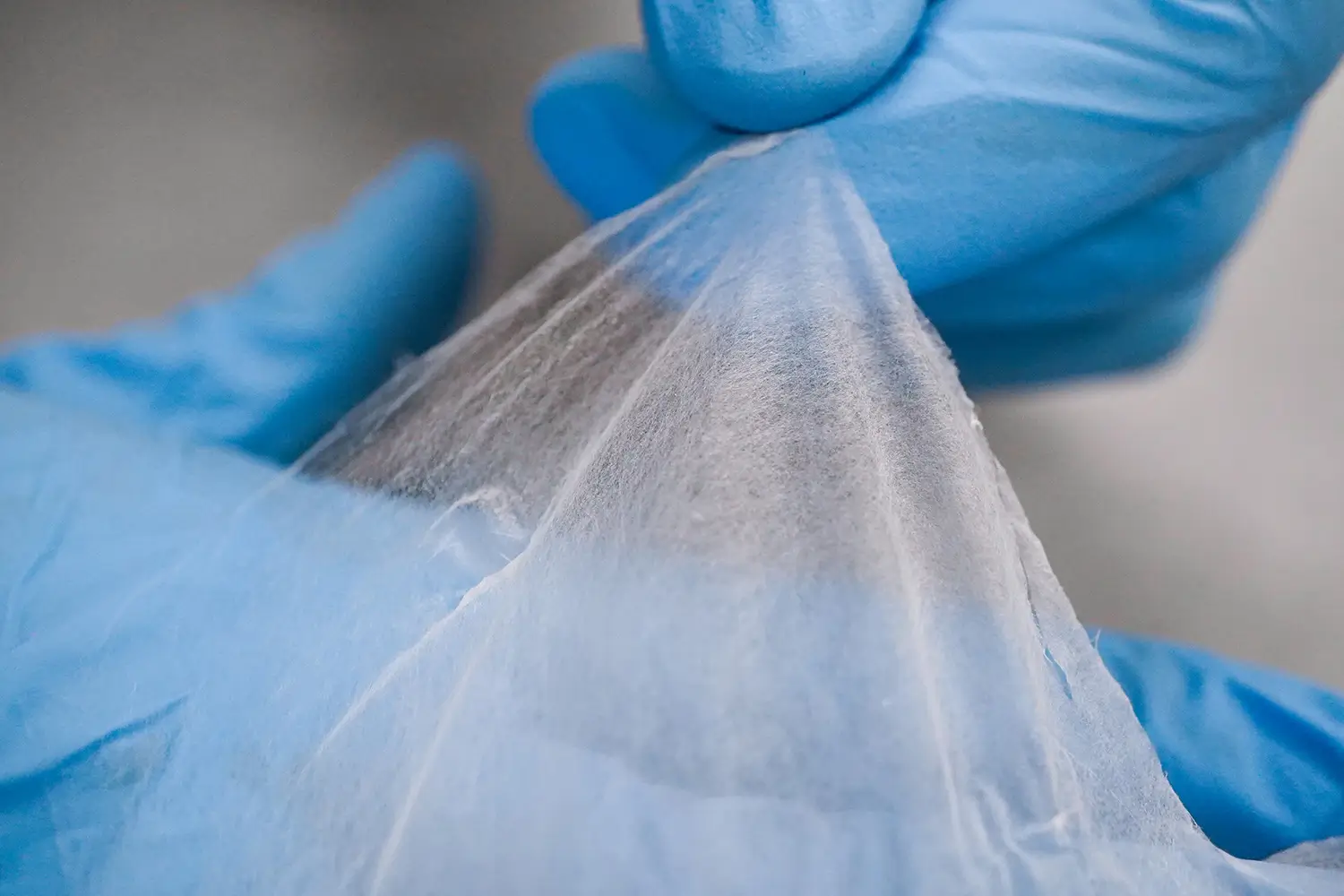

The foundation of a strong partnership begins with material quality. Your chosen nanofiber supplier USA should offer fibers with consistent morphology, controlled diameters, and verified mechanical performance. High-quality nanofibers ensure superior functionality, especially in applications like filtration or medical textiles where precision matters.

Ask potential suppliers about fiber uniformity, reproducibility between batches, and available quality certifications. A reliable company will be transparent and provide documented test results.

2. Evaluate Manufacturing Capabilities and Scalability

Production capabilities vary widely among suppliers. Some excel in small-batch R&D support, while others specialize in large-scale, industrial manufacturing. Understanding each provider’s capabilities helps you determine whether they can keep up with your current and future needs.

A capable nanofiber supplier USA should offer scalable solutions from prototypes to mass production without compromising quality. Flexibility is key, especially for companies expanding product lines or transitioning from concept to commercialization.

3. Look for Advanced Electrospinning Expertise

Nanofiber materials rely heavily on electrospinning technology. The more advanced the technology, the more reliable and customizable the outputs.

Choose a supplier with deep expertise in:

-

Polymer compatibility

-

Solution optimization

-

Multi-layer or composite nanofibers

-

Precise pore structure control

-

Custom material formulations

At Matregenix, our electrospinning knowledge allows us to help clients achieve specific performance targets with high accuracy, making the entire process more efficient and predictable.

4. Review Customization Capabilities

Not all projects fit into a “one-size-fits-all” approach. For many industries, custom nanofiber solutions are essential. Your ideal nanofiber supplier USA should offer extensive personalization options, including fiber diameter control, polymer selection, surface modifications, and integration into unique substrates.

Customization is especially valuable in fields like biomedical engineering, filtration, and energy devices where optimized nanofiber layers can significantly enhance product performance.

5. Assess Regulatory Compliance and Documentation

Industries such as healthcare, aerospace, and automotive require stringent compliance. Your supplier should provide complete documentation, safety data, and regulatory support that aligns with applicable standards.

A reputable supplier will help you navigate compliance hurdles and ensure that your final product meets industry expectations. This level of support reduces delays, prevents costly rework, and strengthens your market readiness.

6. Consider Communication, Collaboration, and Technical Support

Strong communication can make or break a project. Look for a nanofiber supplier USA that provides responsive, knowledgeable support. You should feel confident asking questions, requesting samples, or discussing adjustments without hesitation.

Suppliers who value collaboration can help you refine prototypes, troubleshoot performance issues, and recommend improvements. This team-oriented approach results in better results and faster development cycles.

7. Check Reputation, Reviews, and Industry Experience

Finally, reputation matters. Look for suppliers with proven experience across industries and consistent positive feedback. Companies with established track records demonstrate reliability, innovation, and long-term commitment.

Industry experience also means they’re better equipped to anticipate challenges, offer insights, and guide you through complex material choices. At Matregenix, we’re proud to be recognized as a trusted partner in nanofiber research, development, and manufacturing.

Final Thoughts

Choosing the right nanofiber supplier USA can significantly impact your product’s performance, reliability, and long-term success. By focusing on material quality, expertise, support, and customization capabilities, you can find a partner who aligns with your goals and strengthens your competitive edge.

At Matregenix, we combine scientific precision, advanced nanofiber technology, and customer-first collaboration to help companies innovate with confidence. If you're ready to elevate your next project with high-performance nanofiber solutions, our team is here to support you every step of the way.