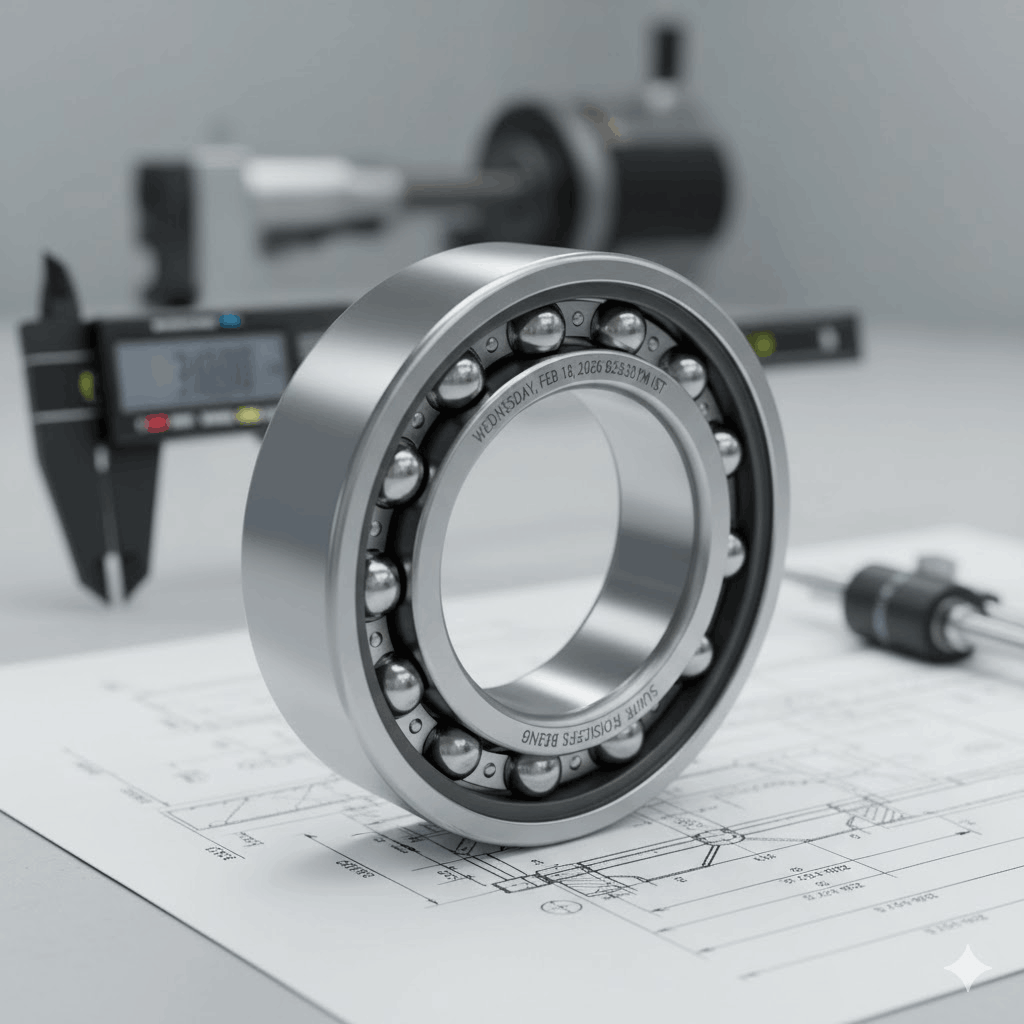

The Super Precision Bearing Market is experiencing strong growth as manufacturers across automotive, aerospace, and industrial sectors seek high-performance components that deliver superior accuracy and durability. With rising demand for advanced machinery and precision equipment, these bearings are becoming indispensable in modern applications.

Key Market Drivers

Three powerful forces are driving the super precision bearing market forward. The first is the rising demand from the aerospace and high-performance automotive sectors. The rapid global shift to electric vehicles (EVs) has created substantial demand for high-load-capacity, precision bearings capable of supporting high-speed EV motors and their auxiliary systems. Simultaneously, growing aircraft engine production — especially next-generation lightweight designs — is accelerating bearing adoption across aviation supply chains.

The second major driver is the rapid growth of semiconductor and medical equipment manufacturing. Semiconductor photolithography equipment requires bearings capable of nanometer-level accuracy, while surgical and dental tools depend on high-speed precision bearings for reliable, contamination-free performance. As miniaturization and ultra-fine processing demands intensify, the need for bearings that offer exceptional speed stability and dimensional accuracy continues to grow.

Request Sample Pages of this Research Study @ https://www.theinsightpartners.com/sample/TIPRE00021133

The third driver is the global integration of Industry 4.0 and advanced factory automation. Smart factories, multi-axis CNC machining centers, and advanced robotics all require bearings that can sustain the tolerances and operating speeds essential for modern precision manufacturing. As automation investment scales worldwide, demand for high-end precision bearing components will continue to rise accordingly.

Market Opportunities

The adoption of hybrid ceramic bearings represents one of the most significant opportunities in this space. Featuring ceramic rolling elements — typically silicon nitride (Si3N4) — combined with steel rings, these bearings offer superior thermal stability, reduced friction, lightweight properties, and extended high-speed capability. Their preference in machine tool spindle applications is rapidly increasing as manufacturers seek to push performance boundaries.

The integration of IoT-enabled, sensor-integrated bearings is another transformative opportunity. Smart bearings with built-in condition monitoring can continuously track vibration, temperature, and load data in real time, enabling predictive maintenance and minimizing unplanned downtime — a highly compelling value proposition for Industry 4.0 adopters. Additionally, rapid industrialization across Asia-Pacific, India, Southeast Asia, and Latin America is opening greenfield opportunities for precision bearing providers looking to expand into high-growth emerging markets.

Order a Copy of this Research Study @ https://www.theinsightpartners.com/buy/TIPRE00021133

Market Segmentation

By type, the market is divided into angular contact ball bearings and cylindrical roller bearings, with angular contact variants dominating due to their suitability for high-speed spindle and axial load applications. By application, machine tool spindles lead the segment landscape, followed by the semiconductor industry, aviation and defense, medical and dental equipment, high-speed turbochargers, and EV automotive systems — each requiring bearings tailored to specific speed, load, and accuracy parameters.

Regional Insights

Asia-Pacific is the fastest-growing regional market, driven by industrial expansion in China, Japan, and India, the semiconductor and electronics manufacturing boom, and strong government support for high-end domestic manufacturing. The region is also rapidly adopting cost-effective hybrid bearing solutions at scale.

North America holds a significant market share, anchored by its mature aerospace, defense, and automotive R&D sectors. The region is leading the shift toward smart, sensor-integrated bearing systems for data-driven operational optimization. Europe commands a strong share, particularly in Germany and Italy, where high-end machine tool manufacturers and major aerospace clusters generate consistent demand for precision bearing solutions. The emphasis on energy-efficient bearing designs and compliance with stringent industrial performance standards is a defining regional trend.

Competitive Landscape

The super precision bearing market is moderately consolidated, with global technology leaders dominating through deep material science expertise and manufacturing precision. Key players include SKF AB (Sweden), Schaeffler AG (Germany), JTEKT Corp (Japan), The Timken Co. (USA), NSK Ltd (Japan), Nachi-Fujikoshi Corp (Japan), NTN-SNR Roulements SA (France), and Luoyang Huigong Bearing Technology Co. Ltd (China). Recent innovations include SKF's ARCTIC15 aeroengine bearing steel for extreme aerospace applications, Schaeffler's AXS and SGL series bearings for robotics and compact machinery, and JTEKT's JIGB® Integrated Gear Bearing for automotive and industrial applications.

Also Available in : Korean German Japanese French Chinese Italian Spanish

Frequently Asked Questions (FAQ)

Q: What is the size of the super precision bearing market?

The market is valued at US$ 10.73 billion in 2025 and is projected to reach US$ 19.55 billion by 2034.

Q: What is the expected CAGR of the super precision bearing market?

The market is anticipated to grow at a CAGR of 6.11% during the 2026–2034 forecast period.

Q: What industries drive demand for super precision bearings?

Key industries include aerospace, electric vehicles (EVs), semiconductor manufacturing, medical and dental equipment, CNC machine tools, and aviation and defense.