Electronic design is often about finding the right balance between size and power. Standard circuit boards work for many things, but they are not always small or tough enough for high-end jobs. This is where specialized microcircuits come into play. They allow engineers to pack more components into a tighter space without losing performance.

The Role of Modern Manufacturers

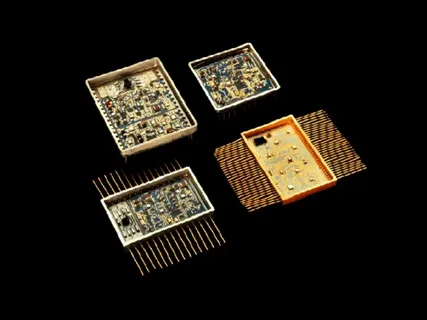

Making these tiny circuits requires a lot of precision. Top Hybrid Microcircuit Manufacturers use a process called thick film technology. This involves printing conductive and resistive pastes onto a ceramic base. The result is a circuit that can handle much higher temperatures than a normal plastic board. This makes them very popular for use in satellites, medical devices, and military equipment where failure is not an option.

Custom Engineering Options

Every project has its own needs. Some require high voltage, while others need to be as light as possible. Using hybrid tec allows designers to mix different parts, like silicon chips and large capacitors, on a single substrate. This flexibility is the main reason why many industries still choose these circuits over standard integrated ones. The components are often adjusted using lasers to ensure the electrical values are exactly right.

Reliability in Harsh Conditions

Standard electronics can struggle with vibration or extreme cold. Because these microcircuits are built on ceramic and often sealed in metal or glass packages, they are much more durable. They are designed to last for years in environments that would destroy a typical smartphone or laptop.

Conclusion

Finding a partner who understands the "print, fire, and trim" process is key to a successful build. Whether you are working on aerospace tech or industrial sensors, quality parts make the difference. Hybrid-Tek offers the experience and cleanroom facilities needed to produce these complex electronic solutions from start to finish.