The global automotive industry is undergoing a fundamental transformation driven by electrification, digitalization, connectivity, and automation. Vehicles are no longer purely mechanical systems; instead, they are becoming sophisticated electronic platforms integrating advanced sensors, control units, communication modules, and intelligent software. This rapid evolution has placed unprecedented importance on protecting electronic components from environmental and operational stresses. Against this backdrop, the Automotive Conformal Coatings Market has emerged as a critical enabler of reliability, safety, and long-term performance in modern vehicles.

According to TechSci Research, the Global Automotive Conformal Coatings Market was valued at USD 2.3 billion in 2024 and is projected to reach USD 3.9 billion by 2030, expanding at a CAGR of 9% during the forecast period. This growth trajectory reflects the expanding footprint of automotive electronics across both passenger and commercial vehicles, as well as the increasing complexity of vehicle architectures.

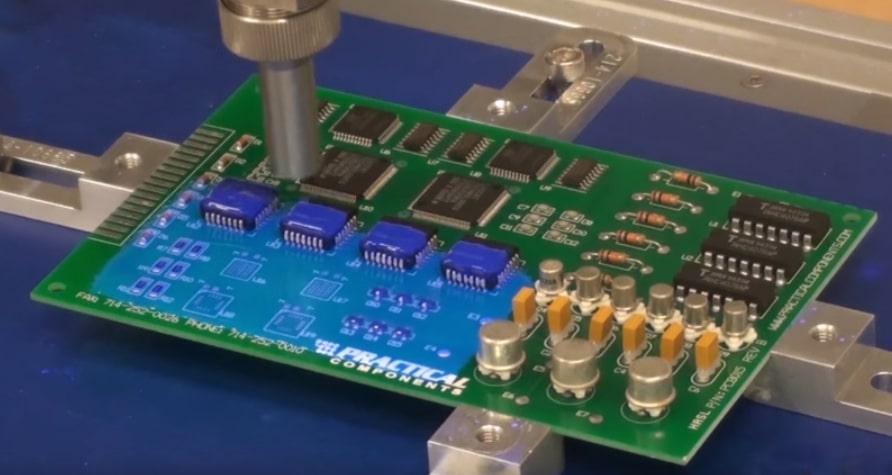

Conformal coatings are thin polymeric films applied to printed circuit boards (PCBs) and electronic assemblies to protect them from moisture, dust, chemicals, salt spray, vibration, and extreme temperatures. In automotive environments—where electronics are exposed to harsh operating conditions such as thermal cycling, humidity, oil vapors, and road debris—these coatings are essential to ensure uninterrupted functionality and long service life.

Market Evolution and Industry Context

The Shift Toward Electronics-Driven Mobility

Over the past decade, automotive innovation has shifted decisively toward electronics-led differentiation. Features such as advanced driver assistance systems (ADAS), infotainment platforms, battery management systems, autonomous driving modules, and vehicle-to-everything (V2X) communication technologies have become integral to vehicle design. Each of these systems relies on densely packed electronic assemblies that must operate flawlessly under varying environmental conditions.

As electronic content per vehicle continues to increase, so does the demand for advanced protection solutions. Automotive conformal coatings have transitioned from being optional protective layers to mission-critical materials that safeguard performance, safety, and regulatory compliance.

Expanding Application Scope

Historically, conformal coatings were primarily used in engine control units and under-the-hood electronics. Today, their application scope has expanded significantly to include:

-

Battery packs and battery management systems

-

Power electronics and inverters

-

ADAS sensors and radar modules

-

Infotainment and connectivity systems

-

Lighting systems and smart headlamps

-

Electronic braking and steering controls

This diversification of applications has fueled demand for coatings with enhanced thermal stability, flexibility, dielectric strength, and chemical resistance.

Download Free Sample Report: https://www.techsciresearch.com/sample-report.aspx?cid=28731

Industry Key Highlights

-

Strong market growth driven by vehicle electrification and connectivity

-

Rising adoption of silicone-based and hybrid conformal coatings

-

Increased use of automated and selective coating processes

-

Growing demand for environmentally compliant, low-VOC formulations

-

Expansion of coating applications across EV and autonomous platforms

-

North America emerging as a high-growth regional market

-

OEMs prioritizing long-term reliability and electronics durability

-

Increased R&D investment in nanocoatings and thin-film technologies

-

Greater emphasis on standardization and quality assurance

-

Competitive landscape characterized by innovation and strategic partnerships

Key Market Drivers

1. Rapid Growth of Automotive Electronics

The proliferation of electronic systems in vehicles is the single most significant driver of the automotive conformal coatings market. Modern vehicles incorporate dozens of electronic control units (ECUs), each responsible for critical functions ranging from powertrain control to occupant safety. Protecting these components from environmental damage is essential to ensure reliability and compliance with safety standards.

2. Electrification of Vehicle Platforms

Electric vehicles (EVs) and hybrid electric vehicles (HEVs) rely heavily on power electronics, high-voltage systems, and battery management technologies. These components are particularly sensitive to moisture, heat, and chemical exposure. Conformal coatings provide essential insulation and protection, enabling stable performance and extending component lifespan.

3. Stringent Safety and Reliability Requirements

Automotive electronics are subject to rigorous safety and reliability standards. Failures in electronic systems can compromise vehicle safety and result in costly recalls. Conformal coatings help manufacturers meet stringent durability requirements by minimizing corrosion, short circuits, and environmental degradation.

4. Increasing Demand for Lightweight and Compact Designs

As automakers strive to reduce vehicle weight and optimize space utilization, electronic assemblies are becoming more compact and densely populated. This increases the risk of moisture ingress and electrical interference, making conformal coatings indispensable for maintaining performance in constrained spaces.

5. Regulatory Push for Environmental Compliance

Global regulations on vehicle emissions, safety, and sustainability are driving the adoption of eco-friendly coating solutions. Manufacturers are increasingly developing low-VOC, solvent-free, and environmentally compliant formulations to align with regulatory expectations.

Emerging Trends Shaping the Market

Adoption of UV-Curable and Hybrid Coatings

UV-curable conformal coatings are gaining traction due to their rapid curing times, reduced energy consumption, and enhanced process efficiency. Hybrid coatings that combine the properties of silicone, acrylic, and polyurethane materials are also emerging, offering tailored performance characteristics for specific automotive applications.

Integration of Automation and Smart Manufacturing

Automated coating systems, including selective coating and robotic spray technologies, are becoming standard in automotive manufacturing. These systems improve consistency, reduce material waste, and enable high-throughput production, supporting large-scale deployment across OEM facilities.

Advancements in Nanotechnology

Nanocoatings and thin-film technologies are enabling enhanced protection with minimal material usage. These innovations offer improved resistance to abrasion, heat, and contaminants while maintaining electrical performance and design flexibility.

Focus on Sustainability and Circular Economy

Sustainability is becoming a key consideration in coating formulation and application. Manufacturers are investing in recyclable materials, solvent-free systems, and energy-efficient processes to reduce environmental impact across the product lifecycle.

Market Segmentation Analysis

By Product Type

-

Acrylic

-

Silicone

-

Polyurethane

-

Epoxy

-

Parylene

-

Others

By Coating Method

-

Brush Coating

-

Spray Coating

-

Dipping

-

Selective Coating

-

Vapor Deposition

By Vehicle Type

-

Passenger Cars

-

Commercial Vehicles

By Application

-

Engine Control Units (ECUs)

-

Battery Management Systems

-

Infotainment Systems

-

ADAS and Safety Systems

-

Lighting Systems

-

Sensors and Connectors

-

Others

By End User

-

Original Equipment Manufacturers (OEMs)

-

Aftermarket

By Region

-

North America

-

Europe

-

Asia-Pacific

-

South America

-

Middle East & Africa

Silicone-Based Coatings: Fastest-Growing Product Segment

In 2024, silicone-based conformal coatings emerged as the fastest-growing product category in the automotive conformal coatings market. Their superior thermal stability, flexibility, and environmental resistance make them ideally suited for demanding automotive applications.

Silicone coatings excel in high-temperature environments, making them particularly valuable for power electronics, battery systems, and under-the-hood components. Their ability to withstand wide temperature fluctuations without cracking or delaminating ensures long-term reliability in electric and hybrid vehicles.

Additionally, silicone coatings offer excellent moisture resistance and dielectric properties, supporting the performance of advanced electronic systems such as radar sensors, infotainment units, and adaptive lighting modules. Their compatibility with automated application processes further enhances their appeal among automotive manufacturers.

Regional Analysis: North America Leading Growth

North America recorded the fastest growth in the global automotive conformal coatings market in 2024. This momentum is driven by strong investment in electric vehicle production, advanced automotive R&D, and the rapid adoption of connected and autonomous vehicle technologies.

The region’s automotive ecosystem emphasizes innovation, safety compliance, and durability, driving demand for high-performance coating solutions. Increased integration of ADAS, V2X communication systems, and intelligent infotainment platforms has significantly expanded the need for electronic protection.

North America’s focus on sustainability and regulatory compliance has also encouraged the adoption of low-VOC and environmentally friendly coatings, reinforcing the region’s leadership position.

Competitive Analysis

The global automotive conformal coatings market is moderately consolidated, with leading players focusing on innovation, product differentiation, and strategic collaborations. Competition is driven by technological expertise, application versatility, and the ability to meet evolving automotive standards.

Key Competitive Strategies

-

Development of advanced, application-specific coating formulations

-

Investment in R&D for sustainable and high-performance materials

-

Expansion of manufacturing and distribution capabilities

-

Strategic partnerships with automotive OEMs and Tier-1 suppliers

-

Emphasis on automation and process optimization

Major Market Players

-

Chase Corporation

-

Dow Inc.

-

Dymax Corporation

-

Elantas (Altana Group)

-

Electrolube (MacDermid Alpha Electronics Solutions)

-

H.B. Fuller Company

-

Henkel AG & Co. KGaA

-

MG Chemicals

-

Momentive Performance Materials Inc.

-

Shin-Etsu Chemical Co., Ltd.

These companies are actively investing in next-generation coating technologies to address the evolving requirements of electric, connected, and autonomous vehicles.

Challenges and Market Constraints

Despite strong growth prospects, the automotive conformal coatings market faces several challenges:

-

High formulation and raw material costs

-

Complex rework and repair processes

-

Lack of uniform global standards

-

Integration challenges with diverse vehicle platforms

-

Need for specialized equipment and expertise

Addressing these challenges will require continued collaboration between material suppliers, OEMs, and regulatory bodies.

Future Outlook

The future of the automotive conformal coatings market is closely tied to the trajectory of automotive innovation. As vehicles continue to evolve into intelligent, connected, and electrified platforms, the importance of reliable electronic protection will only increase.

The market is expected to witness sustained growth driven by EV adoption, autonomous driving advancements, and increasing regulatory scrutiny. Innovations in materials science, automation, and sustainability will shape the next phase of market development, positioning conformal coatings as a cornerstone of automotive electronics reliability.

10 Benefits of the Automotive Conformal Coatings Market Research Report

-

Comprehensive analysis of global and regional market trends

-

In-depth segmentation across products, applications, and vehicles

-

Clear insights into emerging technologies and innovations

-

Detailed competitive landscape and strategic profiling

-

Identification of key growth drivers and market challenges

-

Data-driven market size and forecast projections

-

Evaluation of regulatory and sustainability impacts

-

Strategic insights for OEMs, suppliers, and investors

-

Assessment of regional growth opportunities

-

Support for informed decision-making and long-term planning

Conclusion

The global automotive conformal coatings market is entering a period of sustained expansion, underpinned by the rapid evolution of vehicle electronics and the growing demand for durability, safety, and performance. As automotive platforms become more complex and interconnected, conformal coatings will play an increasingly vital role in enabling reliable, efficient, and future-ready mobility solutions.

By combining technological innovation with sustainability and process efficiency, market participants are well-positioned to capitalize on emerging opportunities and shape the future of automotive electronics protection through 2030 and beyond.

Contact Us-

Mr. Ken Mathews

708 Third Avenue,

Manhattan, NY,

New York – 10017

Tel: +1-646-360-1656

Email: sales@techsciresearch.com

Website: www.techsciresearch.com