Introduction to ABS Plastic Sheet

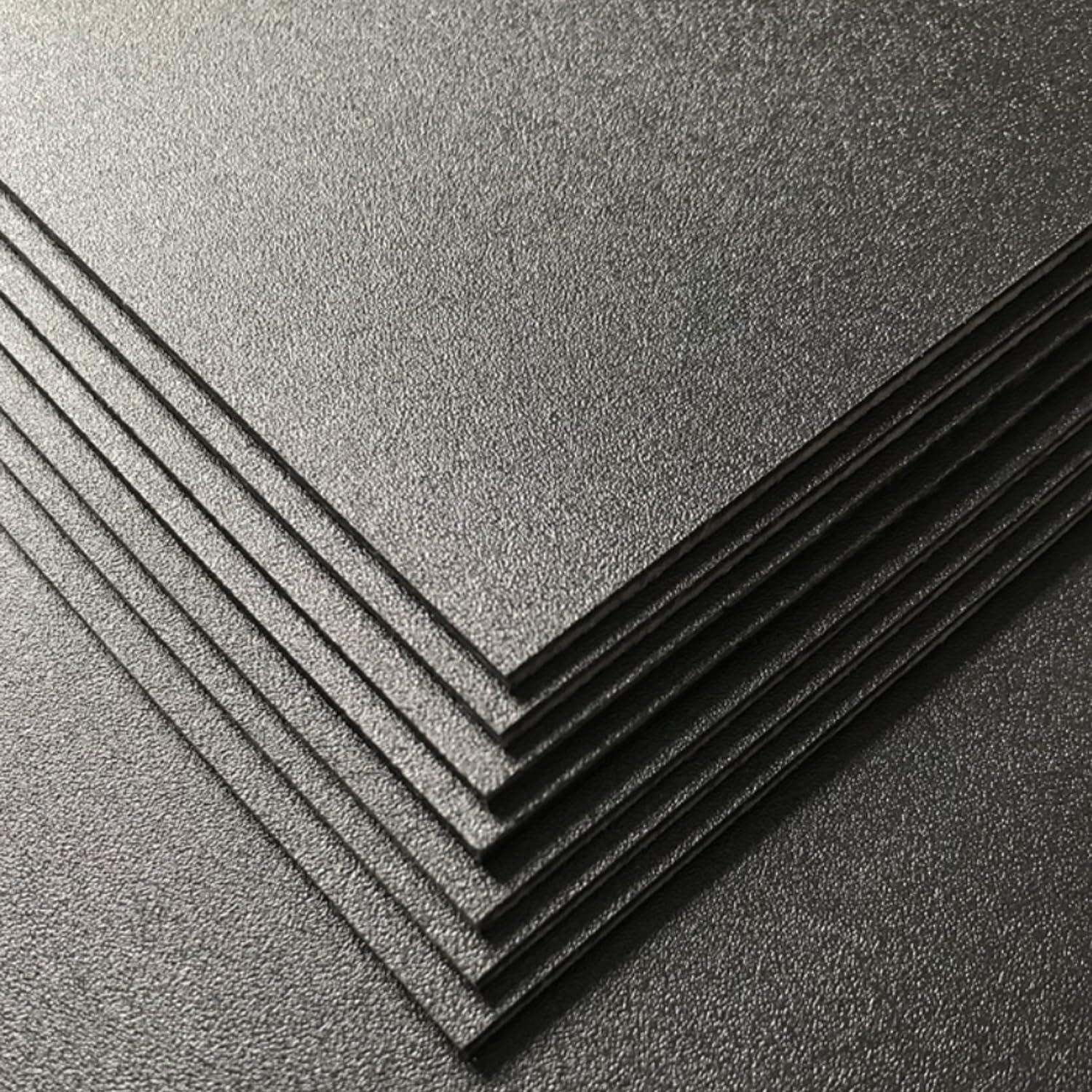

ABS Plastic Sheet has become a very popular material, because it is both easy to use and reuse. ABS is known for its strength, toughness and versatility of aesthetic applications in construction, automotive, packaging, furniture and interior design. With good toughness and nice smooth surface, it is applicable to a variety of functional and decorative applications. With the pace of industrial revolution and technological advancement, the demand of ABS sheets has gone up significantly since when it comes to durability as well as cost- effectiveness, most of Plastic Sheet Manufacturer In India prefer these.

ABS Plastic Sheet and its Composition aucoup

ABS is an acronym for Acrylonitrile Butadiene Styrene, which is a polymer that combines the strength and rigidity of the acrylonitrile and styrene polymers with the toughness of the polybutadiene rubber. The acrylonitrile in it provides the chemical resistance, butadiene gives it impact strenght, and styrene imparts a glossy appearance and ease of processing. Light weigth, thermoformable and easy to fabricate, 3d Wpc Wall Panel Price is an ideal material for applications that require complex shapes. With the ability to withstand heat and moisture, they are built to last even in demanding settings; this is precisely why all ABS Sheet Manufacturer practice seamless quality control.

Multiple uses for Construction and Interior Decorating

In building and interior design applications, ABS plastic is a thermoplastic polymer used for wall panels and furniture. Considering materials in relation to other materials such as 3D wall panels — from 3d Wpc Wall Panel Price and durability, to aesthetics, are also determining factors when architects are specifying a project. ABS sheeting have the advantage of being cost effective, flexible and customisable and as such are a popular choice in architectural application for their modern look.

ABS Plastic Sheets in Automotive and Industrial Uses

The automobile industry uses ABS Plastic Sheets to fabricate various components including light housings, sound systems components and vent louvres. They are light weight in construction which lowers the overall vehicle weight alongside safety requirements. Machine housings, electrical enclosures and safety guards are among the many applications for ABS sheets in industrial sectors. Plastic Sheet Manufacturers In India are setting new standards for plastic sheets with a product that delivers precision, consistency and the kind of long service life customers won’t find anywhere else.

Manufacturing Process and Quality Standards

The ABS Plastic Sheets are produced by either extrusion or thermoforming – preventing impurities and surface defects. A trustworthy ABS Sheet Manufacturer also performs impact tests, thermal stability analysis and dimensional accuracy test on their products. State-of-the-art manufacturing plants allow for customization of color, texture, and form to meet varying industrial and commercial needs while utilizing material efficiently.

Market Situation and Demand in India

With rapid technological developments and affordability, India has emerged as one of the key global plastic manufacturing hubs. There is an upward trend in the demand of ABS sheets for domestic and international market due to which Plastic Sheet Manufacturers In India get good business. Low-cost labor, competitive price of the products and ethical business practices support that India is a significant country in the global ABS Plastic Sheet market.

The Sustainability and Future of ABS Plastic Sheet

ABS the sustainable material to watch The future will be shaped by sustainability Recyclable and biodegradable ABS formulations are desired among manufacturers that want to leave as little impact on the environment as possible As awareness grows, industries are looking for materials that offer both a positive consumer experience and peace of mind When processed properly, using our ABS plastic sheets aids in moving towards circular production models and emits less energy when compared to traditional manufacturing.

Conclusion: Why ABS Plastic Sheets are Still a Smart Option

Summary ABS Plastic Sheet is an ideal option for applications because of its strength, flexibility and versatility. Its versatility is used for applications ranging from construction jobs to automotive quests With consistent reinvention by Plastic Sheet Manufacturers In India, ABS sheets are here to stay as a fundamental material for contemporary industrial and design needs

Frequently Asked Questions (FAQs)

What is an ABS Plastic Sheet?

ABS Plastic Sheets have a wide range of applications as construction panels, automotive components, furniture, stencils and also industrial housings.

Why is ABS Plastic Sheet better than other plastics?

abs plastic sheets offer some of the best characteristics including toughness, rigidity, stiffness and forge and these can be compared with other thermoplastics. they also exhibit superior insulating properties making it an excellent choice for both structural and decorative applications.

Can I used ABS Plastic Sheet outdoors?

In addition, these ABS Plastic Sheets provide resistance to weathering, moisture and temperature fluctuations to maintain its integrity for a long period.

What is the difference between ABS and 3D WPC wall panels?

ABS Plastic Sheets vs 3D Panels: Which Material is Better for Walls Feb 17, 2017 amp;I Three-dimensional panels are great and all, but ABS plastic sheets can do so much more than See the time-lapse video below on one of our recent condo construction projects with ABS seeing that their Will be sure to take this factors in.

Are ABS Plastic Sheets recyclable?

Are ABS Plastic Sheets recyclable to be recycled into other products and as a result supports the use of both new and various production goods very environmentally friendly?

Who is the largest manufacturers of ABS Plastic Sheet?

Singhal Industries Private Limited is a distinguished Manufacturer, Exporter and Supplier of a wide range of Plastic Sheets such as Polypropylene Sheet, HIPS Sheet, HDPE Sheets, PMMA Sheets (Acrylic), PVC Rigid Sheets etc. Reach us to acquire high quality products which are available in different sizes.

Who is the largest exporter of ABS Plastic Sheet?

Singhal Industries Private Limited are reckoned as one of the key companies in international market and we emerge among largest importers of ABS Plastic Sheets that is renowned for their qualitative product, superlative manufacturing techniques and on-schedule deliveries to their customers.

Who is the largest supplier of ABS Plastic Sheet?

Singhal Industries Private Limited is one of the largest ABS Plastic Sheets Manufacturers in RWIND, innovative, capacity and the system quality control good strict production in customer We are producing company.

What are the thicknesses you can supply ABS Plastic Sheets in?

Singhal Industries Private Limited ABS Plastic Sheet can be made from several thicknesses ranging from thin flexible sheet to thick rigid sheets, and it will provide an array of solutions for industry and architecture designs.

Are ABS Plastic Sheets available in custom sizes?

Yes, ABS Plastic Sheets are available in custom colors, textures, size and finish to help designers and manufacturers create aesthetically pleasing products while using a reliable part.