In today’s competitive manufacturing landscape, precision, speed, and consistency are essential. For industries ranging from automotive and electronics to appliance manufacturing, spot welding remains a cornerstone technique for joining metal sheets efficiently. Heron Welder, a global leader in industrial welding and metal-joining solutions, offers advanced spot welder systems and integrated automation solutions tailored to meet the demands of modern factories.

What is a Spot Welder?

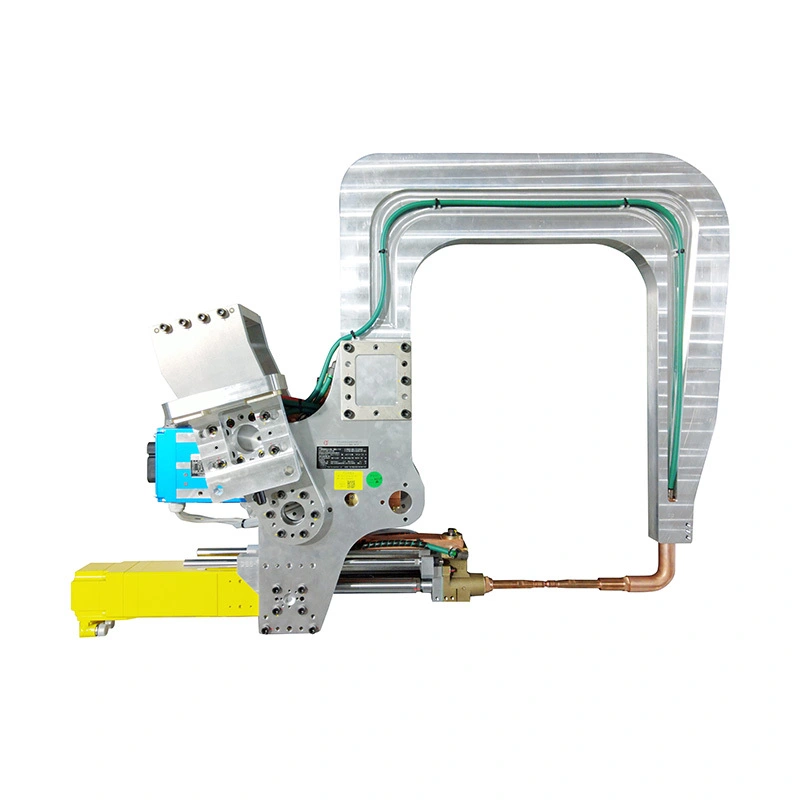

A spot welder is a type of resistance welding machine designed to join overlapping metal sheets by applying heat generated from electrical resistance. The process focuses electrical current through two electrodes, pressing them against the workpieces at the weld point. This localized heat melts the metal and forms a strong, high-quality weld nugget without the need for filler material.

Key benefits of spot welding include:

-

Fast, repeatable welds for high-volume production

-

Minimal material distortion

-

Clean and efficient metal-joining with precise control

-

Compatibility with automated production lines

Heron Welder provides a range of spot welding machines, including capacitor discharge (CD), MFDC, and conventional AC models, allowing manufacturers to choose solutions based on material type, thickness, and production speed requirements.

How a Spot Welder Works: Principles and Process

The operation of a spot welder relies on three main principles:

-

Pressure Application – Electrodes clamp the metal sheets together at the desired weld location. Proper pressure ensures a strong weld and prevents electrode wear.

-

Electrical Resistance Heating – A controlled current passes through the metals, generating heat at the point of contact due to electrical resistance.

-

Cooling and Solidification – Once the current stops, the molten metal cools under pressure, forming a durable weld nugget.

Modern Heron MFDC spot welders integrate advanced microprocessor-controlled power sources to ensure precise current control, optimal weld consistency, and reduced energy consumption.

Applications of Spot Welding

Spot welding is versatile and widely applied across multiple industries:

Automotive Manufacturing

Spot welding is essential for joining car body panels, chassis components, and structural assemblies. With Heron’s automated spot welding lines, OEMs achieve high-speed, repeatable welding for body-in-white (BIW) production.

Electronics and Appliances

From small household appliances to industrial equipment, spot welders efficiently join thin metal sheets and electrical enclosures while maintaining dimensional accuracy.

Heavy Industry and Metal Fabrication

Spot welding is employed for steel structures, HVAC panels, and metal furniture, where durability and strength are critical. Heron’s high-current resistance welders are suitable for both light and heavy-duty applications.

Types of Spot Welders and Their Advantages

Heron Welder offers multiple spot welding technologies, each tailored to specific production needs:

| Type | Ideal Use | Advantages |

|---|---|---|

| AC Spot Welder | General sheet metal | Simple, cost-effective, reliable |

| MFDC Spot Welder | Automotive, thin metals | Precise control, energy-efficient, reduced electrode wear |

| Capacitor Discharge (CD) Spot Welder | Small, delicate parts | Extremely fast welds, minimal heat-affected zone |

| Robotic Spot Welding Systems | High-volume automation | Consistent weld quality, integration with production lines |

By choosing the right spot welding solution, manufacturers can optimize productivity, reduce scrap, and extend electrode life.

Spot Welding Best Practices

Maximizing weld quality requires careful attention to process parameters:

-

Material Thickness and Type – Adjust current and pressure based on steel, aluminum, or coated materials.

-

Electrode Maintenance – Regular cleaning and dressing prevent inconsistent welds.

-

Proper Alignment – Ensure electrodes are perpendicular to the workpiece for uniform welds.

-

Cooling Time – Allow sufficient cooling to prevent weak weld nuggets or distortion.

Heron’s advanced spot welder controllers automate many of these parameters, ensuring reproducible results while minimizing human error.

Spot Welder vs. Other Welding Methods

While spot welding excels in sheet metal joining, it differs from other welding techniques:

-

MIG/TIG Welding: Provides versatility and stronger single joints but is slower and less suited for high-volume production.

-

Seam Welding: Creates continuous welds along edges, ideal for tubing or tanks, but requires more complex machinery.

-

Laser Welding: Offers precision for thin metals and delicate components, though at higher equipment costs.

Spot welding remains the preferred solution when speed, efficiency, and cost-effectiveness are critical for overlapping metal sheets.

Why Choose Heron for Spot Welding Solutions?

Heron Welder combines engineering expertise, global manufacturing experience, and advanced automation technologies to deliver spot welding solutions tailored to customer needs:

-

Fully customizable welding cells and robotic lines

-

Expertise in resistance, MFDC, and CD spot welding technologies

-

Integration with production line monitoring and quality control systems

-

Global support for OEMs, manufacturing engineers, and automation integrators

Heron doesn’t just supply machines—it provides complete welding solutions that improve efficiency, reduce downtime, and enhance product quality.

Frequently Asked Questions (FAQs)

1. Can spot welding be used for aluminum sheets?

Yes. Heron MFDC spot welders are specifically designed for aluminum, with precise current control to prevent weld defects.

2. How thick can a spot welder handle?

Spot welding thickness depends on the machine type and power. Heron machines handle thin sheets up to 6 mm or more, depending on the model.

3. What is the difference between MFDC and AC spot welders?

MFDC welders provide more precise current control, reduced electrode wear, and higher efficiency, especially for thin or coated metals, compared to conventional AC machines.

4. Can spot welding be automated?

Absolutely. Heron integrates robotic arms and controllers for fully automated spot welding lines suitable for high-volume production.

5. How is weld quality ensured?

Heron uses advanced monitoring, programmable controllers, and process parameter optimization to ensure consistent weld nuggets and minimal defects.

Take Your Manufacturing to the Next Level

Whether you are optimizing automotive production, electronics assembly, or heavy metal fabrication, Heron Welder’s spot welding solutions offer precision, speed, and reliability.

Contact Heron today to discuss your production needs, request a quote, or design a fully customized welding and automation solution that meets your exact manufacturing requirements.