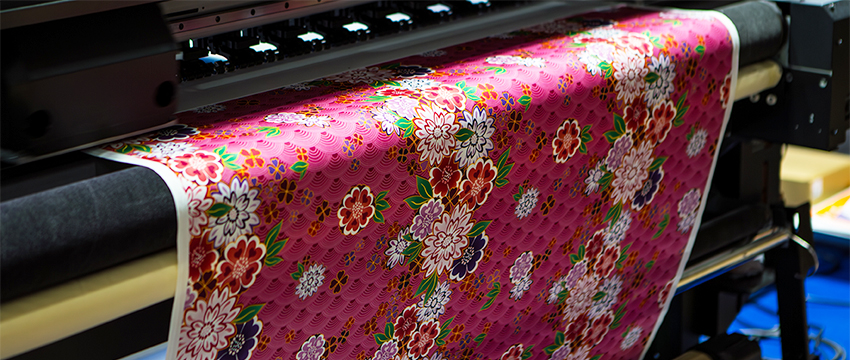

The textile and fashion industries have undergone revolutionary changes over the past two decades, thanks in large part to advancements in digital technologies. Among these, digital printing on fabric stands out as one of the most transformative innovations. Once dominated by traditional screen printing, the textile printing industry now increasingly favors digital techniques for their efficiency, sustainability, and ability to support intricate designs with exceptional detail.

Digital textile printing refers to the process of applying color to fabric using inkjet technology. Unlike conventional methods, which require screens or plates for each color, digital printing transfers designs directly from computer files to fabric. This article explores the fundamentals of digital fabric printing, its methods, benefits, applications, challenges, and future trends.

What is Digital Printing on Fabric?

Digital printing on fabric is a process where designs are printed directly onto textiles using specialized inkjet printers and textile inks. This technique eliminates many of the steps required in traditional textile printing, such as creating screens or setting up plates, and enables short runs, customization, and rapid prototyping.

The process involves:

-

Preparing the digital artwork.

-

Pre-treating the fabric if necessary.

-

Printing using inkjet printers.

-

Post-processing (fixation and washing) to set the colors.

This technology can be used on a wide range of textiles including cotton, silk, polyester, linen, and blends, depending on the type of ink and fabric treatment applied.

Types of Digital Fabric Printing Techniques

Direct-to-Fabric (DTF) Printing

This method involves printing directly onto the fabric using inkjet printers. The fabric is usually pre-treated to enhance ink absorption and color fastness. DTF is suitable for both natural and synthetic fibers, depending on the ink used.

Dye Sublimation Printing

Ideal for polyester and polymer-coated fabrics, dye sublimation involves printing a design onto a transfer paper using sublimation inks. Heat and pressure are then applied to transfer the ink from the paper to the fabric, turning the dye into gas without becoming liquid — a process known as sublimation.

Pigment Printing

Pigment inks are water-based and can be printed directly onto a variety of fabrics. They require less post-treatment but may not offer the same vibrancy or softness as other inks. However, they are more environmentally friendly and efficient for short runs.

Reactive and Acid Ink Printing

These are used for natural fibers like cotton (reactive) or silk and nylon (acid). They require a steaming process to fix the colors and offer high color vibrancy and wash durability.

Advantages of Digital Printing on Fabric

Design Flexibility

Digital printing enables designers to experiment with colors, patterns, and gradients without limitations. Unlike traditional printing, which is constrained by screen separations, digital files can contain millions of color combinations and photo-realistic images.

Cost-Effective for Short Runs

There is no need for expensive screen creation, making digital printing ideal for small batches, custom items, or samples. Startups and independent designers especially benefit from this flexibility.

Faster Turnaround Times

Digital printing significantly reduces the time between design and production. This supports on-demand production and allows fashion brands to keep up with fast-changing consumer trends.

Sustainability

Digital printing uses less water, fewer chemicals, and produces minimal waste compared to conventional dyeing and screen printing. Eco-conscious brands are increasingly shifting to digital methods to reduce their environmental footprint.

High Precision and Quality

Because the printer applies the ink with pinpoint accuracy, digital printing achieves fine details and smooth color transitions that are hard to match with traditional methods.

Common Applications

Digital fabric printing is widely used across various industries:

-

Fashion and Apparel: Custom clothing, limited-edition collections, personalized T-shirts, and accessories.

-

Home Textiles: Upholstery, curtains, bed linen, and wall coverings.

-

Sportswear and Activewear: High-performance prints on synthetic fabrics.

-

Soft Signage: Banners, flags, and exhibition graphics.

-

Art and Interior Design: Fabric-based artworks, tapestries, and customized interiors.

Challenges and Considerations

Despite its numerous benefits, digital printing on fabric also presents some challenges:

-

Initial Investment: High-end digital textile printers and fabric treatment equipment can be expensive.

-

Ink Costs: Specialized inks are more costly than traditional dyes and may need special handling.

-

Fabric Compatibility: Not all fabrics are suitable for every ink type; proper pre-treatment is often necessary.

-

Color Matching: Achieving consistent color across different materials and printers can be complex.

These limitations are gradually being addressed with ongoing innovation in print heads, software, and eco-friendly ink formulations.

FAQs About Digital Printing on Fabric

Is digital fabric printing suitable for all types of fabrics?

Not all fabrics respond equally to digital printing. Cotton, silk, polyester, and blends can be printed digitally, but they often require specific ink types and pre-treatments. Polyester is ideal for dye-sublimation, while cotton works best with reactive or pigment inks.

How durable are digitally printed fabrics?

With the correct ink and fixation method, digitally printed fabrics can be very durable. Reactive and sublimation prints, for example, offer high wash and light fastness. Pigment prints are improving in durability with modern formulations.

Can I print photographic images on fabric?

Yes. One of the biggest advantages of digital printing is the ability to reproduce high-resolution photographic images with precision, making it popular for custom clothing, home décor, and art applications.

Is digital printing eco-friendly?

Digital printing is generally more sustainable than traditional methods. It uses significantly less water and chemicals, reduces fabric waste, and supports on-demand production, which minimizes overproduction and surplus stock.

How does digital printing compare to screen printing?

Screen printing is ideal for large-volume production with limited color palettes. Digital printing is better suited for complex, colorful designs and short to medium runs. It offers greater versatility but can be more expensive for very high-volume jobs.

Future Trends in Digital Textile Printing

The global digital textile printing market is growing rapidly, driven by demand for personalization, sustainability, and supply chain flexibility. According to market research, this industry is expected to exceed USD 8 billion by 2030.

Emerging trends include:

-

On-demand fashion and just-in-time manufacturing.

-

Integration of AI and automation in design and production workflows.

-

Use of biodegradable or plant-based inks.

-

3D fabric printing and smart textiles.

Technological advancements will continue to improve print speeds, reduce costs, and expand compatibility with various fabrics — making digital textile printing even more accessible and efficient.

Conclusion

Digital printing on fabric is more than just a technological upgrade — it’s a paradigm shift in how textiles are designed, produced, and consumed. By enabling greater creativity, faster turnaround, and sustainable practices, digital printing is reshaping the fashion and textile landscape.

Whether you're a designer aiming for intricate patterns, a manufacturer seeking efficiency, or a consumer looking for personalized apparel, digital printing offers endless possibilities. As the technology matures, it will continue to democratize the textile industry, empowering creators while reducing environmental impact.