The continuity and integrity of concrete structures, particularly in hostile conditions, pose a perpetual challenge to civil masterminds and possessors. declination by sharp chemicals, abrasive inflow, and microbial convinced erosion( MIC) can mainly weaken concrete over time, performing in precious form, early relief, and loss of operation. An effective long- term result is demanded to help these from passing. This is where the HDPE T- Rib liner sheet are a better protection system, furnishing an impermeable guard with outstanding chemical resistance and mechanical harborage.

The Need for High Tech Concrete Protection

Concrete, though extremely common and natural in strength, is vulnerable. Its previous face offers entry to aggressive chemicals like sulfates, chlorides, and organic acids that target the cementitious matrix. In seamster systems, bacterial conversion of hydrogen sulfide gas to sulfuric acid is a notorious lawbreaker that causes quick declination of concrete shells. Conventional defensive coatings tend to have compromised adhesion, brief lifetime, and propensity to blistering or cracking, rendering them infelicitous for critical, long- term systems. A veritably effective remedy should only repel these assaults but continue to be stuck with the structure ever, icing protection for numerous decades.

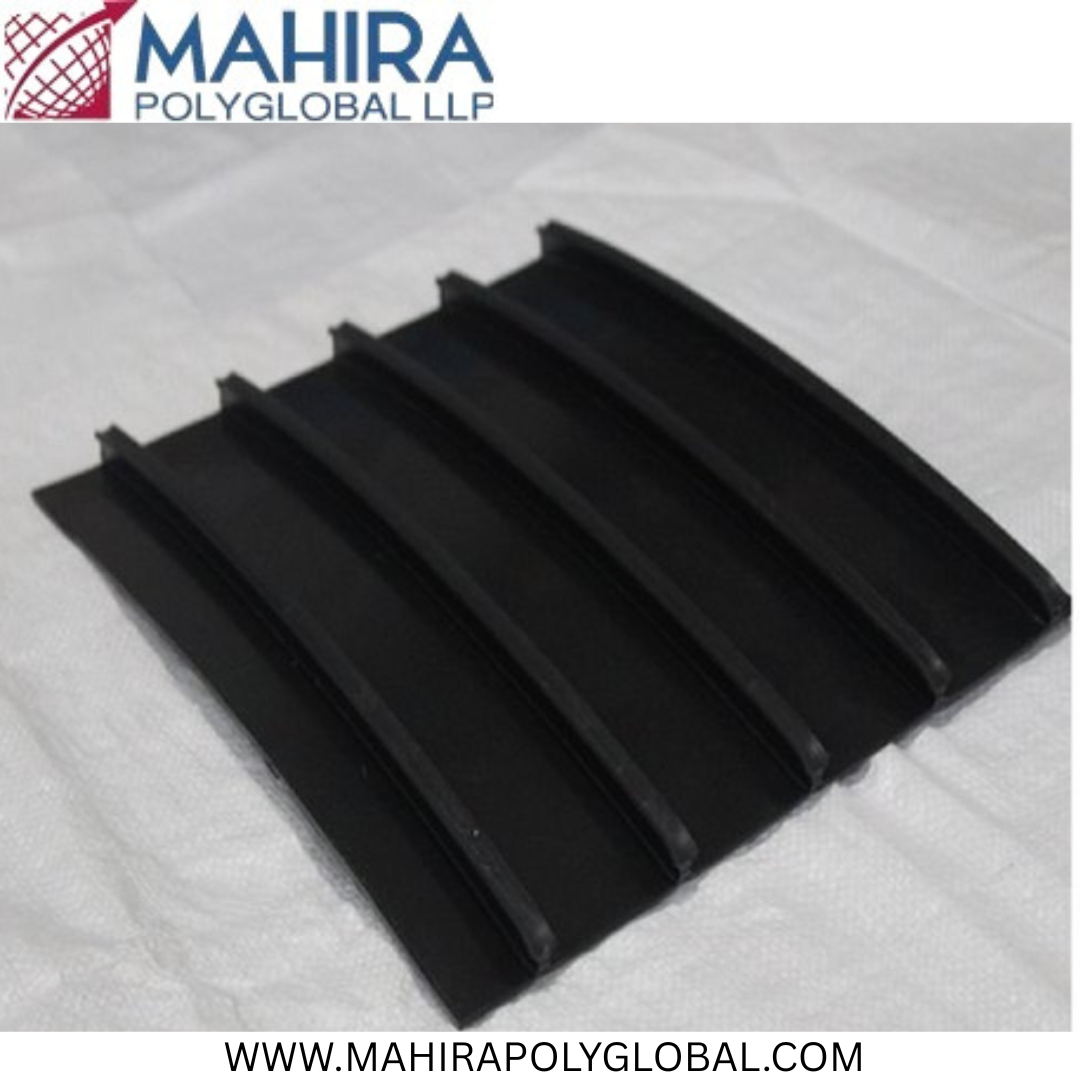

Learning about the HDPE T- Rib Liner Sheet Technology

The substance of the HDPE T-Rib liner sheets technology is their geometrically different form and composition. High- viscosity Polyethylene( HDPE) is a thermoplastic polymer used extensively due to its great chemical resistance, high strength- to- viscosity, and durability. In discrepancy to utmost polymers, HDPE is resistant to a veritably broad diapason of chemicals and, thus, is particularly suited for operations in wastewater treatment shops, seamster systems, chemical storehouse areas, and coverts. The crucial specific of these sheet is the integrally extruded, anchor- type" T" caricatures. The caricatures are formed to come physically reprised in the concrete mass when it's cast, forming a mechanical interlock that's basically thick.

Installation and Mechanical Anchorage

The installation is simple but veritably effective. The HDPE T- Rib liner sheet are generally clicked to the inner formwork previous to concrete placement. When the concrete blend is poured and vibrates, it settles around the T- caricatures, completely boxing them. After the concrete has cured, the sheet becomes fixed into the structure. This physical bond removes the typical failure areas for tenacious- reliant stuffings, similar as debonding, delamination, and hydrostatic uplift. The strong physical anchor wo n't have the liner peel out, indeed with high pressure or temperature changes, creating a homogenous, unbroken defensive shell.

The part of the HDPE T- Rib Liner Manufacturer in Quality Assurance

The quality of the finished product is largely dependent on the manufacturer's moxie and product norms of the HDPE T-Rib liner manufacturer. High- grade sheet should be manufactured exercising virgin HDPE resin to give ideal performance parcels, similar as zero porosity and invariant chemical resistance. Manufacturers use accurate extrusion styles to guarantee the T- caricatures are constantly shaped and sized for maximum anchoring strength. In addition, quality control addresses weldability since the sheet will need to be thermally welded on- point into a flawless liquid-tight hedge. A believable manufacturer inventories material certified to meet rigid transnational norms for consistence, viscosity, tensile strength, and ESCR.

Crucial Performance Benefits Chemical, Abrasion, and Temperature Resistance

The HDPE T- Rib liner's performance is multidimensional. Chemically, HDPE is stable at the exposure to pH between 1 and 14, thereby fighting the extremely acidic conditions current in extremely deteriorated seamsters as well as the alkaline conditions of new concrete. This renders it the stylish result for aseptic and artificial concrete operations. Mechanically, the sheet possesses advanced bruise resistance, which is essential in high- inflow channels and channels where suspended solids may erode typical concrete shells. Its capability to flex permits it to gauge small gaps in the concrete substrate without undermining the defensive filling. In addition, HDPE performs well over a wide range of temperatures, allowing for the thermal expansion and compression of the concrete structure without hardening or getting too flexible.

Operations Over a Wide Variety of structure systems

The versatility of the HDPE T-Rib liner permits operation in a large variety of structure systems. It's an integral part in the design of new wastewater treatment factory tanks, pollutants, and headworks, offering long- term erosion protection on the first day of operation. In tunneling and channel construction, the liners are applied to shield precast parts or cast- in- place concrete from sharp groundwater and internal inflow. They're also more and more specified for chemical storehouse vessels, secondary constraint structures, and mining installation structures where chemical attack is a main issue. The capability to knitter sheet sizes and use internal or external welding adds to its versatility in addressing complicated shapes.

Life Cycle Cost Analysis and Life

The Mahira Polyglobal LLP is economically profitable from the life cycle cost standpoint. Though original costs are lesser than for conventional face treatments, the estimated life of the HDPE liner generally exceeds 50 to 100 times before expansive conservation or relief is demanded. This expansive reduction in long- term conservation and recuperation cost represents a considerable return on investment. masterminds totaling up the cost of power discover that preventing the necessity for periodic precious shutdowns and repairs decisively cock the scale in favor of mechanically anchored liner system compared to temporary or less flexible options. It's indeed an investment in structure adaptability.

Conclusion

The use of HDPE T- Rib liner sheet is a turning point in concrete protection technology. By incorporating the inert, largely chemical- resistant nature of HDPE with a strong, endless mechanical anchoring system, this result fully neutralizes the major hazards of concrete deterioration in hostile surroundings. The sheet offer an unequaled , confluence- welded, and completely integrated defensive cover. Defining this technology guarantees critical concrete structure, ranging from seamster pipe networks to chemical processing vessels, to remain safe from erosion and bruise over numerous generations, reducing conservation costs and assuring functional life of vital public and artificial means.

Frequently Asked Questions

Question: What separates a mechanically attached HDPE T-Rib liner from a typical glued-on geomembrane?

A: The primary distinction lies in the attachment method and long-term reliability. A typical geomembrane depends on chemical adhesives or tapes for joining to the concrete, which can fail due to chemical attack, thermal cycling, and hydrostatic pressure, causing delamination.

Question: Are HDPE T-Rib liner sheets suitable for rehabilitating existing deteriorated concrete structures?

A: Although HDPE T-Rib liner sheets are used mainly for new work where they are poured into the new concrete, specialized versions or application methods can be utilized for repair.

Question: How is the integrity of the continuous impermeable barrier maintained when several HDPE T-Rib liner sheets are spliced in the field?

A: The sheets are welded together onsite with specialized thermal welding machines, a procedure that is essential to establishing a leak-proof liquid-tight seal the two most utilized techniques are hot wedge welding or extrusion welding.

Question: Who is the largest supplier of HDPE T-Rib Liner Sheet?

Answer: Although a number of companies across the world produce HDPE T-Rib Liner Sheets Mahira Polyglobal LLP is a well-known manufacturer and exporter of high-quality sheets that can be used for concrete protection in industrial projects.

Question: Who is the largest exporter of HDPE T-Rib Liner Sheet?

Answer: A number of manufacturers ship HDPE T-Rib Liner Sheets across the world Mahira Polyglobal LLP is also a major exporter distributing its high-density polyethylene sheets abroad for use in projects.

Question: Who is the largest manufacturer of HDPE T-Rib Liner Sheet?

Answer: The manufacturing sector for HDPE T-Rib Liner Sheets includes numerous global firms. Mahira Polyglobal LLP is one of the specialized manufacturers known for producing durable and chemical-resistant T-Rib Liner Sheets.

Question: What is an HDPE T-Rib Liner Sheet used for?

Answer: HDPE T-Rib Liner Sheets are especially utilized to shield concrete infrastructure, including sewage pipes, tunnels, and wet wells against corrosion due to hostile chemicals, acids and gases like.

Question: What is the method of installation of the HDPE T-Rib Liner Sheet?

Answer: The sheets are usually placed before curing of the concrete with the T-shaped ribs acting as mechanical anchors. The sheet joints are subsequently welded through techniques such as butt welding or extrusion welding for an unbroken, protective coating.

Question: Why are HDPE T-Rib Liner Sheets chemical resistant?

Answer: The High-Density Polyethylene (HDPE) material itself offers superior resistance to a broad variety of corrosive acids, chemicals, and solvents and due to this characteristic it is perfectly suitable for wastewater and chemical containment applications.

Question: Is HDPE T-Rib Liner Sheet customizable?

Answer: Yes well established makers such as Mahira Polyglobal LLP tend to provide customization regarding thickness width length and color the particular needs of various construction and infrastructure projects.